As the core of modern energy storage technology, lithium batteries have been widely used in mobile electronic equipment, electric vehicles and other fields. The performance and stability of lithium batteries largely depend on the quality of the pole pieces. As one of the key production links, lithium battery pole piece slitting is of great significance to improve battery performance and stability.

Pole piece slitting technology

Lithium battery electrode slitting technology refers to the process of cutting the positive and negative electrode materials of lithium batteries into specified sizes. This step requires a high degree of precision and stability to ensure the consistent size of each pole piece, thus safeguarding the performance and life of the battery. Commonly used pole piece slitting methods include mechanical cutting, laser cutting, etc.

Mechanical cutting

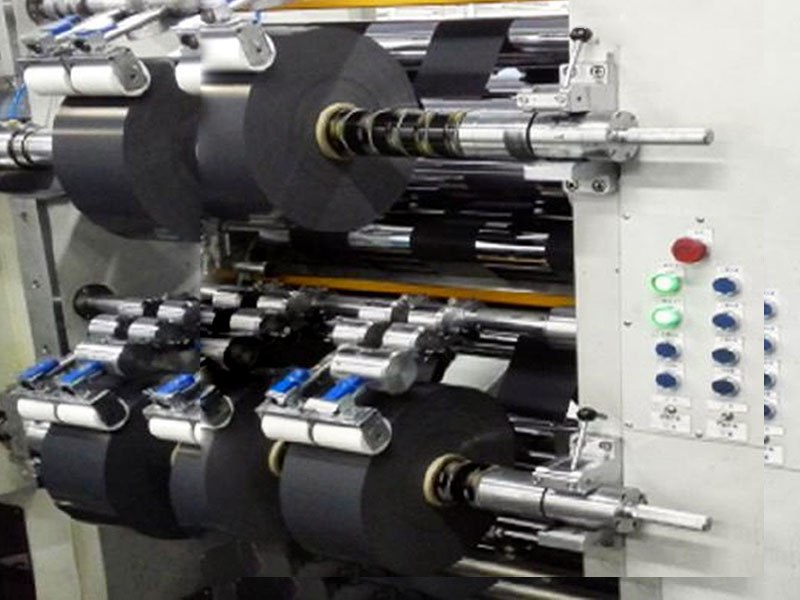

Mechanical cutting is one of the most common pole piece slitting methods. It utilizes mechanical equipment, such as a slitting machine or slicer, to achieve the separation of pole pieces by cutting with a knife. This method is relatively inexpensive, but there are issues such as tool wear and dimensional accuracy that need to be considered.

Laser cutting

Laser cutting is a non-contact slitting method that uses the focusing of a laser beam to achieve precision cutting. Laser cutting has the advantages of high precision, no contact and no pollution, and is suitable for scenarios that require high electrode size and surface quality.

The importance of pole piece slitting

Lithium battery electrode slitting plays an important role in the energy storage industry:

Improve battery performance: The accuracy of pole piece slitting directly affects the performance and cycle life of the battery. Precise slitting can ensure the consistency of the electrode piece and improve the energy density and output performance of the battery.

Reduced production costs: Precise electrode slitting can reduce scrap rate and reduce production costs. By optimizing the slitting process, the utilization rate of materials can be improved and production costs can be reduced.

Promoting industrial development: With the rapid development of electric vehicles and other fields, the demand for lithium batteries is increasing. Efficient and precise electrode slitting technology will promote the development of lithium battery industry.

Future outlook

With the continuous innovation in the field of energy storage, the slitting technology of lithium battery pole pieces will also continue to improve. High-precision and high-efficiency slitting technology will become an important part of lithium battery production and provide strong support for the development of energy storage industry. With the progress of science and technology and the continuous optimization of technology, the slitting technology of lithium battery pole pieces will make greater breakthroughs in the future and help the energy storage industry move to a higher level.

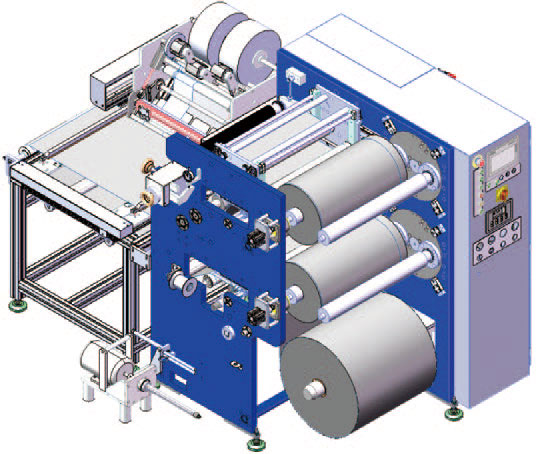

Equipment for high-speed, high-precision slitting of wide metal strips (such as aluminum strips, nickel strips, or copper-aluminum composite strips) into the required width and number of tabs.

27. October, 2025

According to the design requirements of the battery cell, cut it into multiple narrow strips with consistent width, neat edges, and no burrs.

17. October, 2025

This is achieved through a system engineering that combines mechanical engineering, materials science, automatic control and sensing technology.

12. September, 2025

The technical level of the slitting machine directly determines the yield, quality consistency of the separator, and the safety and performance of the final battery.

27. August, 2025

Below I will elaborate on how to improve cutting quality through parameter optimization from three aspects: core parameters, optimization strategies, and systematic methods.

22. August, 2025