In the production process of lithium battery, slitting machine is one of the indispensable and important equipment. It is mainly responsible for cutting electrode belts, separators and other materials into the required length and width according to the specified specifications for subsequent battery assembly work. The cutting accuracy and efficiency of lithium battery slitting machine have an important impact on the performance and production efficiency of the battery, so it is important to choose high-precision and high-efficiency equipment and maintain and manage it well.

1. The working principle of lithium battery slitting machine

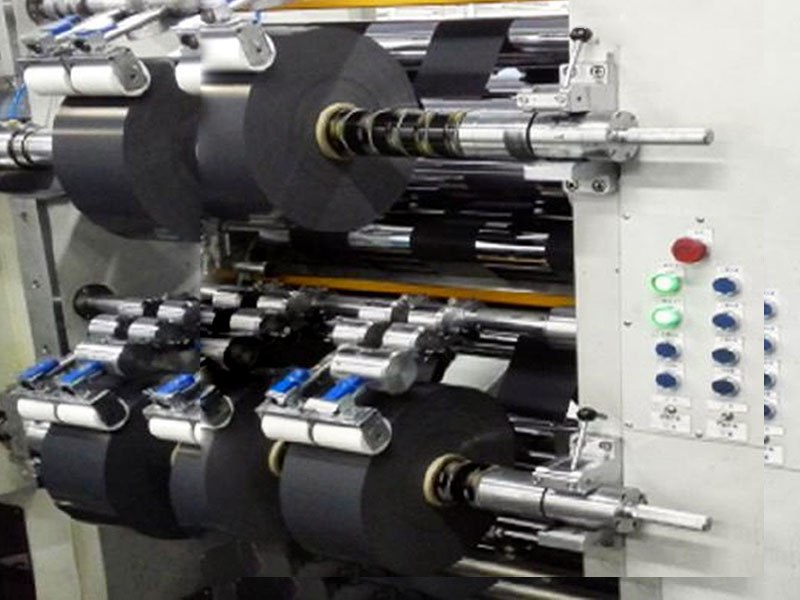

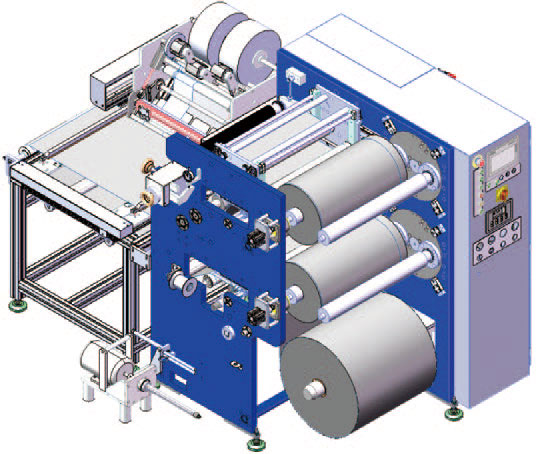

The lithium battery slitting machine is usually composed of a blanking system, a feeding system, a positioning system, a cutting system, a receiving system and other parts. During the working process, the blanking system will blank the large pieces of material into small pieces of material of appropriate size, and then feed them into the slitting machine through the feeding system. The positioning system precisely locates and transfers small pieces of material to the cutting system, which typically uses a high-speed rotating disc cutter to slit. The slitted material is collected through a receiving system for the next step in the battery assembly process.

2. The characteristics of lithium battery slitting machine

High precision: The lithium battery slitting machine adopts advanced cutting technology and control system to ensure that the cutting accuracy meets the preset requirements to improve the performance and stability of the lithium battery.

High efficiency: Through the high-speed rotating cutting tool and the optimized feeding mechanism, the lithium battery slitting machine can achieve fast and continuous slitting operations and improve production efficiency.

Automation: The lithium battery slitting machine has the functions of automatic feeding, automatic cutting and automatic receiving, which reduces manual intervention and errors, and reduces labor costs.

Strong adaptability: The lithium battery slitting machine is suitable for slitting tasks such as electrode belts and separators of different specifications and materials, and can be flexibly adjusted according to production needs.

3. The application field of lithium battery slitting machine

Lithium battery slitting machines are widely used in lithium battery production industries, including small consumer electronics, electric vehicles, energy storage systems and other fields. It provides an efficient and precise cutting solution for the production of lithium batteries, and promotes the continuous development and application expansion of lithium battery technology.

4. The future development trend of lithium battery slitting machine

With the continuous expansion of the lithium battery market and the continuous progress of technology, the lithium battery slitting machine will continue to develop in the direction of intelligence, efficiency and environmental protection. In the future, the lithium battery slitting machine will pay more attention to the linkage and integration with upstream and downstream equipment to realize the automation and intelligence of the production line. At the same time, through the introduction of advanced cutting technology and material handling technology, the lithium battery slitting machine will further improve the cutting speed and accuracy, reduce energy consumption and emissions, and promote green production.

summary

As one of the key equipment in the production process of lithium battery, the characteristics of high precision and high efficiency of lithium battery slitting machine are very important to improve the performance and production efficiency of lithium battery. Through continuous technological innovation and application expansion, the lithium battery slitting machine will continue to make important contributions to the development of the lithium battery industry. At the same time, we should also pay attention to the future development trend of lithium battery slitting machine to adapt to the changing market demand and promote the sustainable development of lithium battery production.

Equipment for high-speed, high-precision slitting of wide metal strips (such as aluminum strips, nickel strips, or copper-aluminum composite strips) into the required width and number of tabs.

27. October, 2025

According to the design requirements of the battery cell, cut it into multiple narrow strips with consistent width, neat edges, and no burrs.

17. October, 2025

This is achieved through a system engineering that combines mechanical engineering, materials science, automatic control and sensing technology.

12. September, 2025

The technical level of the slitting machine directly determines the yield, quality consistency of the separator, and the safety and performance of the final battery.

27. August, 2025

Below I will elaborate on how to improve cutting quality through parameter optimization from three aspects: core parameters, optimization strategies, and systematic methods.

22. August, 2025