The rewinder is generally used for the rewinding and slitting of mica tape, paper and film, and is widely used. Below, Xiaobian will tell you how to do a good job in the daily maintenance and maintenance of the rewinder.

The daily maintenance of the rewinder must ensure that the inside and outside of the computer instrument box are clean and dry; Regularly check that the terminal blocks are not loose or fall off. Ensure that the circuit and gas path are unblocked. The specific maintenance is as follows:

1. Regularly check the screws of each part of the packaging machine to avoid loosening;

2. Pay attention to the waterproof, moisture-proof, anti-corrosion and rodent-proof parts of the electrical parts. The inside of the electric control box and the terminals should be kept clean to prevent electrical failure;

3. When the machine is stopped, the two heat sealing rollers should be in the open position to prevent scalding of the packaging materials;

4. Regularly lubricate the gear meshing of the rewinder, the oil injection hole of the seated bearing and the moving parts. When filling the lubricating oil, please be careful not to drop the oil on the transmission belt, so as to prevent slipping and losing or aging damage to the belt;

5. The newly installed rewinder must be inspected and fastened, refueled and maintained within one week of use; Maintenance must be checked regularly every month thereafter.

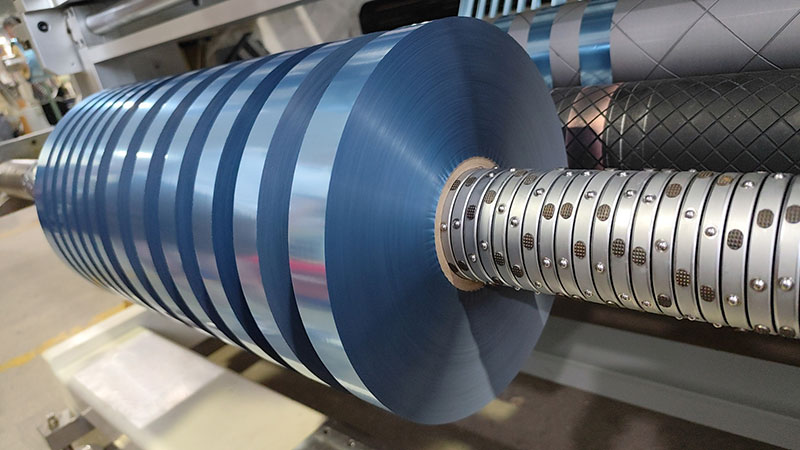

The stable operation of the slitting rewinder is the basis for producing high-quality coil products.

10. December, 2025

Precisely cut the wide master roll according to the preset dimensions, then rewind it into finished rolls suitable for subsequent processing or direct use.

09. December, 2025

Cut wide rolls of film, paper, nonwoven fabric, metal foil, and other materials to precise sizes, and then rewind them into finished rolls that meet downstream requirements.

09. December, 2025

A slitting rewinder is a device that slices wide coils into multiple narrow strips of material and rewinds them into independent rolls.

09. December, 2025

A suitable slitting and rewinding machine can not only greatly improve production efficiency, but also reduce material loss and ensure product quality.

08. December, 2025