In the production process of lithium batteries, pole piece slitting is a crucial link. As the core component of lithium battery, the slitting accuracy and quality of the pole piece directly affect the performance and production efficiency of the lithium battery. This article will introduce the principle, key technologies and applications of lithium battery pole piece slitting in detail, aiming to help readers better understand this critical step.

First, the principle of lithium battery pole piece slitting

Lithium battery pole piece slitting is mainly the use of high-precision cutting equipment to cut the pole piece according to the preset size and shape. During the cutting process, it is necessary to ensure the sharpness and precision of the cutting tool, as well as the control of cutting speed and force, so as to ensure that the cut pole piece has a consistent size and shape.

Second, the key technology of lithium battery pole piece slitting

1. High-precision cutting technology: Lithium battery pole piece slitting requires extremely high precision to ensure that the size and shape of each pole piece meet the preset requirements. Therefore, it is necessary to use high-precision cutting equipment and technology, such as laser cutting, mechanical cutting, etc.

2. Cutting speed and force control: The control of cutting speed and force is very important for the quality of pole piece slitting. Too fast cutting speed or too much force may cause the pole piece to be cut unevenly or burr, affecting the performance of the lithium battery.

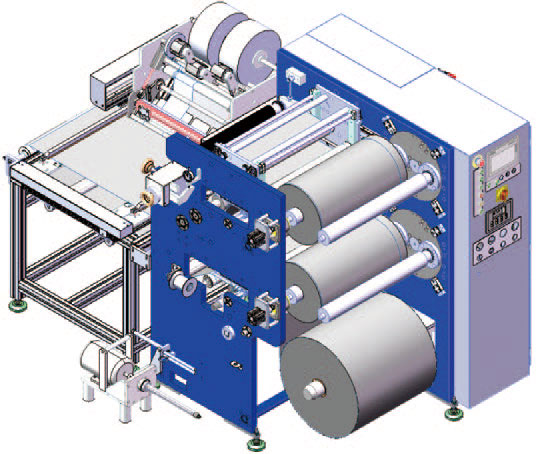

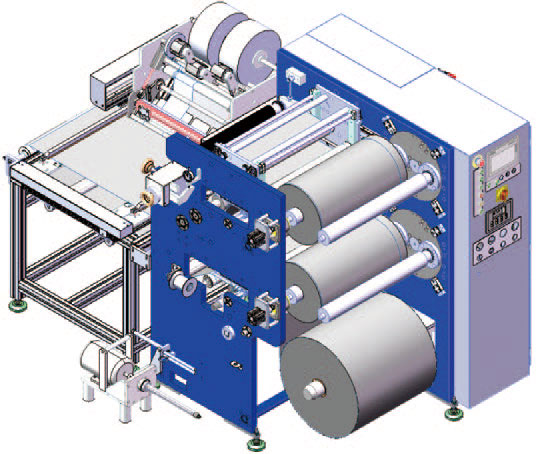

3. Automation technology: In order to improve production efficiency and reduce human intervention, automation technology is adopted in the slitting process of lithium battery pole piece, such as automatic feeding, automatic cutting, automatic blanking, etc.

Third, The application of lithium battery pole piece slitting

Lithium battery electrode slitting is widely used in the production process of various types of lithium batteries, including small consumer electronics, electric vehicles, energy storage systems, etc. Through pole piece slitting, it can be ensured that the pole piece of each lithium battery has a consistent size and shape, so as to ensure the performance and consistency of lithium batteries.

Fourth, summary

As a key step to improve the production efficiency and performance of batteries, lithium battery electrode slitting plays an important role in the production process of lithium batteries. Through the use of high-precision cutting technology, reasonable control of cutting speed and strength, and the application of automation technology, the quality and efficiency of pole piece slitting can be ensured, and a strong guarantee can be provided for the high-quality production of lithium batteries. With the continuous expansion of the lithium battery market and the continuous progress of technology, the lithium battery electrode piece slitting technology will also continue to develop and innovate, bringing more convenience and value to the production of lithium batteries.

Equipment for high-speed, high-precision slitting of wide metal strips (such as aluminum strips, nickel strips, or copper-aluminum composite strips) into the required width and number of tabs.

27. October, 2025

According to the design requirements of the battery cell, cut it into multiple narrow strips with consistent width, neat edges, and no burrs.

17. October, 2025

This is achieved through a system engineering that combines mechanical engineering, materials science, automatic control and sensing technology.

12. September, 2025

The technical level of the slitting machine directly determines the yield, quality consistency of the separator, and the safety and performance of the final battery.

27. August, 2025

Below I will elaborate on how to improve cutting quality through parameter optimization from three aspects: core parameters, optimization strategies, and systematic methods.

22. August, 2025