As a key equipment in modern industrial production, slitting machines are widely used in textile, packaging, electronics, automobiles and other fields, playing an important role. According to the specific needs of different industries, the slitting machine continuously improves its flexibility and efficiency in material processing through technological innovation and customized design. Today we will introduce the role and optimization of slitting machines in processing in different industries.

In the textile industry, slitters are optimized to handle a wide range of fibers and fabrics, from light and thin silks to heavy fabrics, to achieve uniform and non-destructive cutting, meeting the diverse cutting needs of apparel and home textiles. Through the introduction of laser or ultrasonic cutting technology, it shows the advantage of high precision in complex pattern processing.

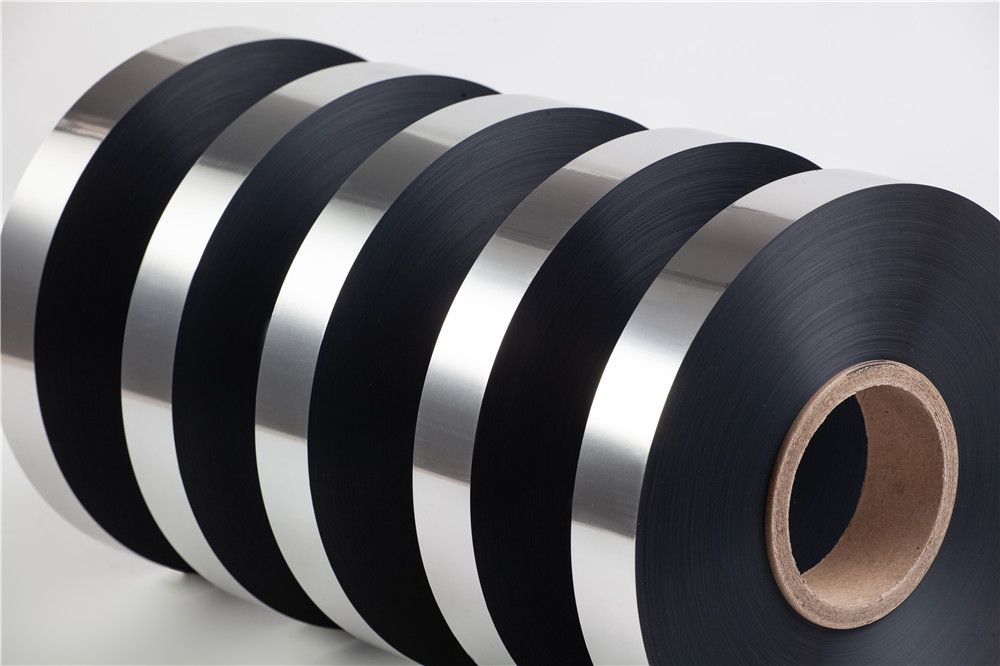

In the field of packaging, the slitting machine needs to adapt to a variety of materials such as plastic film, paper, metal foil, etc., through high-speed continuous cutting and precise control of margins, to ensure the output and quality stability of packaging materials, and provide strong support for FMCG and electronic product packaging.

In the electronics manufacturing industry, the slitting machine focuses on the precision cutting of thin materials such as circuit boards and protective films, and uses microcomputer control and visual positioning systems to ensure that the cutting accuracy reaches the micron level and meets the strict standards of precision components.

Slitting machines are also widely used in the automotive industry, especially in the processing of interior materials, leather, and soundproofing materials, through customized knives and powerful flattening devices, to achieve the cutting of complex shapes, and improve the accuracy and productivity of component assembly.

To sum up, through continuous technological innovation and the expansion of application scenarios, the slitting machine has optimized its own performance, promoted the progress of processing technology and the improvement of production efficiency in various industries, and demonstrated its core value in diversified applications.

The leap in its core competitiveness stems from the comprehensive empowerment of intelligent control technology.

11. February, 2026

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026

a sophisticated system that combines mechanical engineering, materials science, and intelligent control.

11. February, 2026

This article will comprehensively analyze the functional system of ribbon slitting machine and reveal how it achieves precise control from raw materials to finished products.

10. February, 2026

a machine that completes the three functions of slitting, rewinding and detection at the same time, and ribbon production ushers in an era of integrated intelligence.

10. February, 2026