In the precision machining process of modern manufacturing industry, the slitting machine has become the key equipment to improve the efficiency of the production line with its high-speed and accurate cutting ability and good operation efficiency.

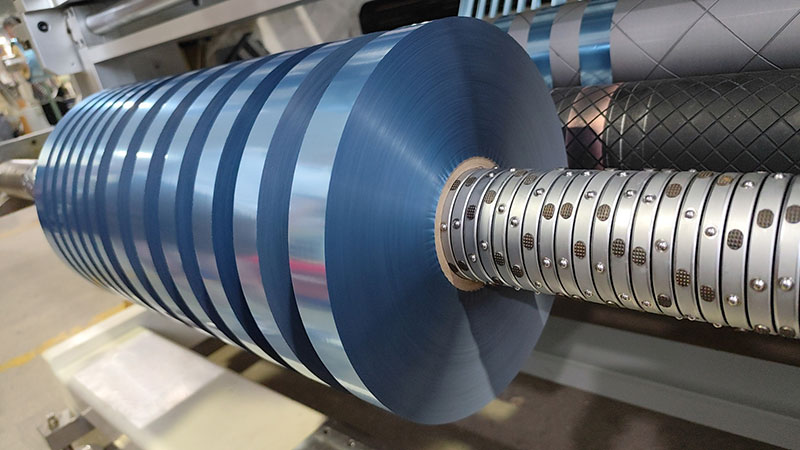

The biggest highlight of the slitting machine is the integration of advanced servo drive technology and precision tooling system, which can achieve fast and accurate cutting of materials, whether it is thin as a cicada's wing or thick and tough composite materials, it can show consistent cutting accuracy, greatly reducing the scrap rate.

In the second in-depth analysis, the reason why the slitting machine can achieve efficiency doubling is inseparable from its intelligent control system and highly automated design. The system can automatically adjust the cutting speed, pressure and path according to the material characteristics and cutting requirements, and is equipped with an automatic feeding, winding and tension control system to ensure continuous and stable high-speed operation, reduce manual intervention, and improve the overall production efficiency and continuous operation ability.

The third time is to emphasize that the slitting machine shows high flexibility and adaptability in the face of diversified and customized market demand. It supports quick tool change and adjustment configuration to meet the cutting needs of materials of different widths and thicknesses, and is widely used in packaging, textile, electronics, automobile and other industries, becoming an important force to promote industrial upgrading and intelligent manufacturing.

To sum up, the slitting machine with high-speed and accurate cutting and high-efficiency operation of the comprehensive performance, not only optimizes the production process, reduces costs, but also provides manufacturers with a strong production capacity, is a powerful assistant to achieve high-efficiency and high-quality production, and constantly promotes the development of the manufacturing industry in a more refined and intelligent direction.

The leap in its core competitiveness stems from the comprehensive empowerment of intelligent control technology.

11. February, 2026

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026

a sophisticated system that combines mechanical engineering, materials science, and intelligent control.

11. February, 2026

This article will comprehensively analyze the functional system of ribbon slitting machine and reveal how it achieves precise control from raw materials to finished products.

10. February, 2026

a machine that completes the three functions of slitting, rewinding and detection at the same time, and ribbon production ushers in an era of integrated intelligence.

10. February, 2026