In the highly competitive manufacturing environment, good slitting machine manufacturers continue to promote technological innovation and improve processing accuracy to meet the market demand for fast rate and high-precision slitting operations. By combining advanced mechanical design concepts with precision manufacturing technology, these manufacturers have created slitter equipment that can cope with a wide variety of materials, improve production efficiency, and ensure cutting quality.

Innovative design highlights

1. Chemical control system: PLC control and touch screen operation interface are introduced to realize parameter preset, automatic speed regulation, fault alarm and other functions, simplify the operation process, and improve production flexibility and automation.

2. Servo drive technology: Driven by high-response servo motor, combined with precision ball screw or linear guide, it ensures accurate control of cutting speed and high-precision positioning of position, and can keep the cutting edge straight and smooth even under high-speed operation.

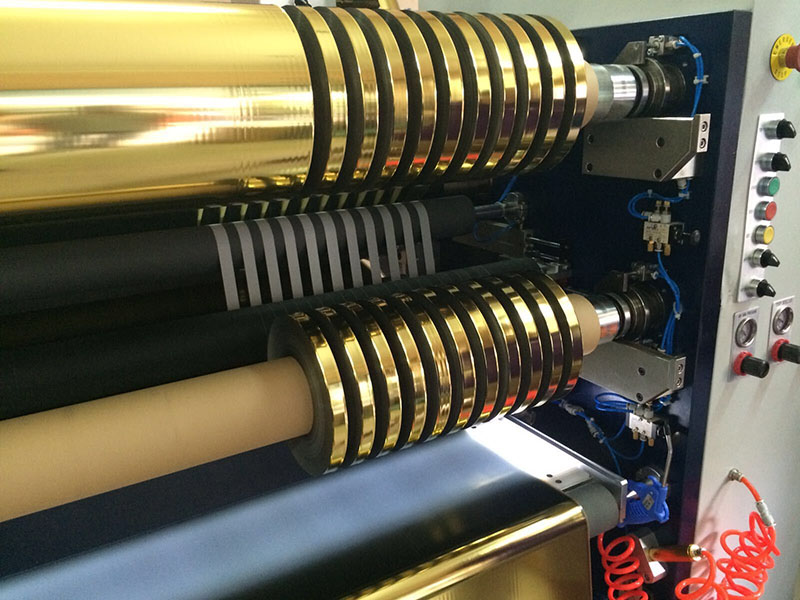

3. Multi-cutter head design: The development of multi-cutter head synchronous working system not only improves the slitting efficiency, but also adjusts the cutter pitch according to the material characteristics to meet the slitting needs of materials of different widths and thicknesses, and increases the versatility and adaptability of the equipment.

4. Automatic tension control: Integrate advanced tension control system to dynamically adjust the coil tension to avoid relaxation or deformation of the material during the slitting process, and ensure the consistency and stability of cutting quality.

Strategies to improve machining accuracy

• Precision machining equipment: Invest in five-axis linkage machining centers, laser cutting machines and other equipment to improve the machining accuracy of parts, reduce assembly errors, and lay the foundation for the high-precision operation of the whole machine.

• Strict quality control: The established quality management system, from raw material inspection to finished product testing, implements strict testing standards in each process to ensure that each slitting machine reaches the state before leaving the factory.

• Continuous technology research and development: Set up a dedicated R&D team, continuously study material characteristics and cutting technology, optimize tool design and cutting algorithm through simulation analysis, experimental verification and other methods, and improve the overall machining accuracy.

epilogue

Through continuous innovative design and improvement of processing accuracy, slitting machine manufacturers not only provide users with fast and reliable slitting solutions, but also promote the technological progress and industry of the entire industry. In the future, with the integration of manufacturing and Internet of Things technology, the slitting machine will be more flexible to further meet the personalized and customized market demand, and promote the manufacturing industry to a higher stage of development.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026