As an important equipment in modern manufacturing, especially in the field of film and cloth processing, the accurate and fast operation ability of the slitting machine plays an important role in improving production efficiency and ensuring product quality. Through the application of advanced technology, the slitting machine can not only achieve accurate cutting of materials, but also meet the needs of large-scale continuous production, which significantly improves the market competitiveness of processing enterprises.

1. Fine processing of film processing

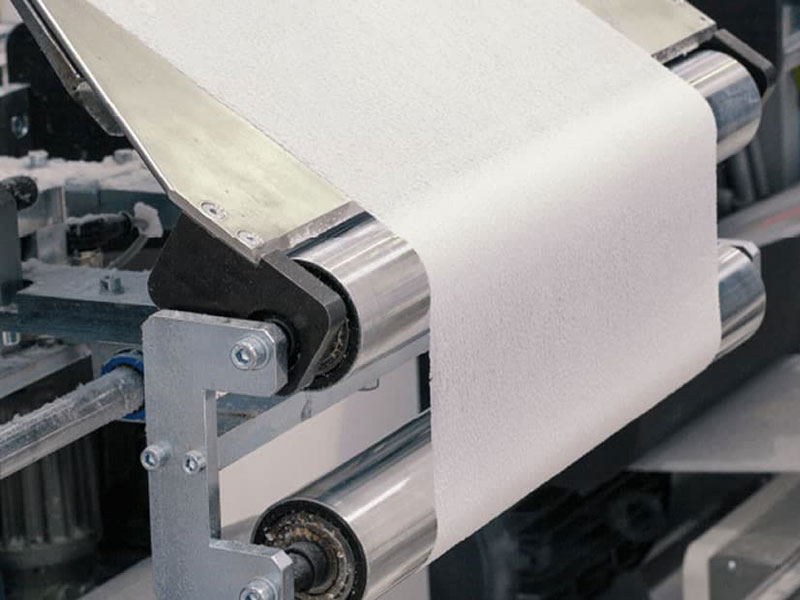

In the film industry, such as the production of plastic films, composite films, optical films, etc., the slitting machine can ensure that the film materials can still obtain high cutting accuracy under high-speed operation, and minimize edge burrs and dimensional errors. Equipped with an automatic web guiding system and a tension control system, it can achieve stable and wrinkle-free slitting even for films with a thickness of a few microns, which is especially important in high-tech fields such as electronics, packaging, and optoelectronics.

2. Flexibility and efficiency in fabric processing

For the textile market, slitters demonstrate their flexibility when handling a wide range of fabrics. Whether it's light silk, heavy canvas or functional fabric, the slitter achieves an even, damage-free cut by adjusting the tool configuration and optimizing the feed rate. Especially for high-volume orders, the automated slitting production line can significantly shorten the production cycle, reduce manual intervention, improve the utilization rate of fabrics, and reduce costs.

3. The trend of customization and customization

The modern slitting machine also integrates technologies such as the Internet of Things and big data analysis to realize the functions of remote monitoring and fault warning, so that production management is more refined and standardized. At the same time, in the face of diversified market demand, slitting machine manufacturers provide customized services, according to the specific needs of customers, such as material characteristics, output requirements, etc., design special slitting solutions, to further improve the pertinence and efficiency of processing.

In short, the application of slitter in film and cloth processing, with its accurate cutting control, fast production capacity and increasing level, is constantly promoting the transformation of these two industries to a better quality and faster production model, bringing greater value and competitive advantage to manufacturers.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026

It is not only production equipment, but also a key lever for enterprises to leverage profit growth by reducing costs, increasing efficiency and improving quality.

28. February, 2026