As an indispensable processing equipment in the manufacturing industry, slitting machines are widely used in cutting and slitting of plastic films, metal foils, paper, non-woven fabrics and other materials. With the increasing diversification of the needs of various industries, slitting machines are no longer limited to standardized production, but go deep into the market segment and provide customized services for the specific needs of different fields to meet the requirements of different materials, thicknesses, precision and output.

1. Plastic film industry

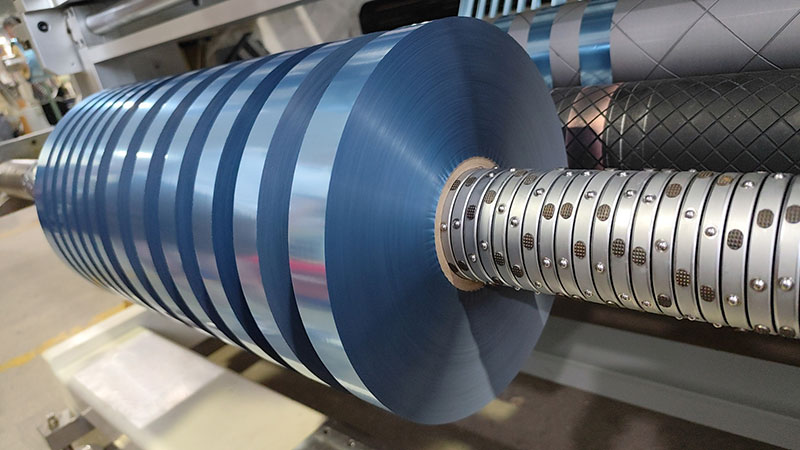

In the field of plastic packaging, slitting machines need to have high-speed, high-precision cutting capabilities to adapt to thin and soft film materials. Special requirements include anti-static devices, constant temperature control to avoid film deformation, and an automatic web guiding system to ensure continuous and stable production. The customization service also takes into account the width of the film, the number of layers and the special cutting needs of the composite film.

2. Metal foil processing

The metal foil slitting machine needs to be equipped with a high-strength cutting head and a stable tension control system to cope with the hardness and toughness of the metal material. Dustproof and waterproof design is also necessary to ensure the stable operation of the equipment in the environment of metal chips. The customized service will adjust the tool material and cutting speed according to the thickness, strength and subsequent processing requirements of the metal foil.

3. Paper processing

Paper slitting machines emphasize cutting accuracy and efficiency, especially for high-demand materials such as printed matter and label paper. Customization takes into account the grammage, smoothness and roll diameter of the paper, providing accurate slitting control and edge handling to reduce waste and maintain paper integrity.

4. Non-woven fabric industry

The non-woven fabric slitting machine needs to have the ability to handle soft materials to avoid material stretching or damage. Cleaner production and reduced dust pollution are key, especially for the slitting of nonwovens for medical use. Customized services will focus on cleanroom-compatible design, sharpness retention of tools, and quick-change systems to meet hygienic standards.

To sum up, slitting machines in different fields need to provide highly customized solutions according to material properties and industry specifications. Through an in-depth understanding of customer needs, the manufacturer adopts advanced technology and design concepts, and continuously optimizes the function and performance of the slitting machine, in order to stand out in the highly competitive market and provide customers with more focused and faster slitting services. This trend of customization not only enhances the added value of products, but also promotes the technological progress and service of the entire slitter industry.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026