A slitting rewinder is a versatile industrial equipment that can be used to process many types of materials. Here are some common materials that can be applied to slitting rewinders:

1. Paper: including various types and thicknesses of paper, such as printing paper, wrapping paper, kraft paper, etc. The slitting rewinder can cut large rolls of paper into small rolls suitable for different purposes and re-roll them.

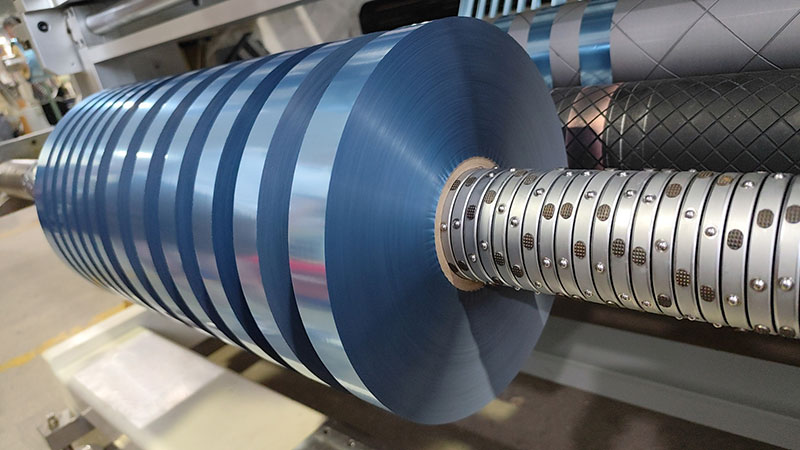

2. Plastic film: such as polyethylene (PE), polypropylene (PP), polyester (PET) and other materials. These films are often used for packaging, protection, fixing, etc. The slitting rewinder can cut it to the desired width and rewind it.

3. Metal foil: such as aluminum foil, copper foil, etc. These metal foils have excellent electrical, thermal and barrier properties, and are widely used in food packaging, electronic components and other fields. The slitting rewinder can slit it into the required width and length to meet different application needs.

4. Textiles: including fabrics, non-woven fabrics, etc. These materials are widely used in clothing, home furnishing, medical and other fields. The slitting rewinder can cut it to the desired size and shape and rewind it.

5. Rubber membranes: such as rubber and plastic membranes, waterproof membranes, etc. These materials have a wide range of applications in construction, automotive, electronics and other industries. The slitting rewinder can cut and rewind it as needed.

6. Special materials: such as mica tape, insulating materials, etc. These materials have special application needs in specific industries and can be processed by slitter rewinders as well.

In addition, the slitting rewinder can also handle some materials with special properties, such as adhesive tapes, protective films, etc. These materials require special attention to tension control and cutting accuracy during the slitting and rewinding process to ensure the quality of the final product.

Overall, slitting rewinders have a wide range of applications and can handle many types of materials. When choosing a slitting rewinder, it is necessary to consider the specific material type, processing requirements and production efficiency to ensure that the most suitable equipment is selected.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026