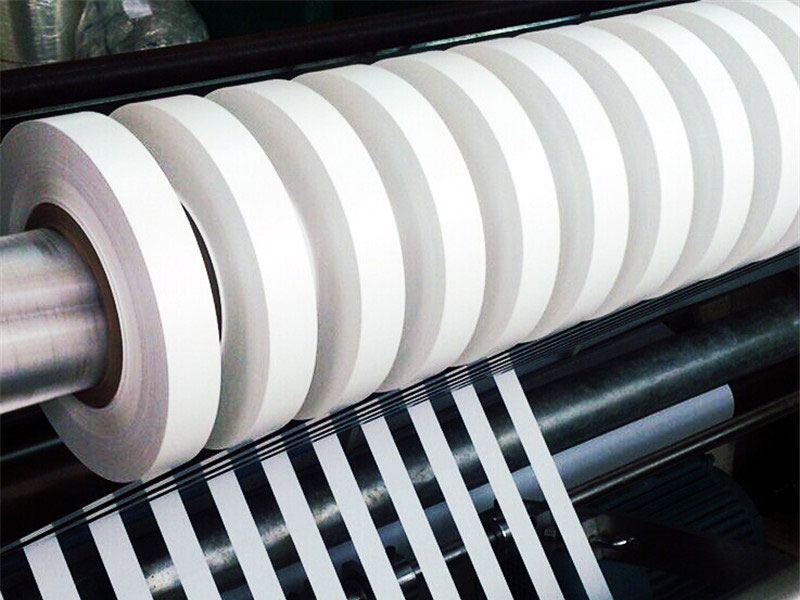

Slitting rewinder has a wide range of applications in various industries, it is mainly used to cut raw materials from large rolls into small rolls, as well as to rewind. Here are some of the main materials that are suitable for slitter rewinders:

1. Paper: In the paper and printing industry, slitting rewinders are often used to cut large rolls of paper into small rolls to meet the needs of different uses. These small rolls of paper may be used for printing, toilet paper production, or other special purposes.

2. Textiles: In the textile industry, slitting rewinders are used to process various textiles, such as fabrics, fibers, etc. These materials are usually purchased in large rolls and then cut into smaller rolls as needed.

3. Film: In the packaging, printing and electronics industries, slitting and rewinding machines are often used to process various film materials, such as PET film, protective film, release film, polyester tape, foam, EVA, etc. These materials need to be rewound in specific widths and lengths for use in subsequent processing or use.

4. Metal foils: In the electronics industry and some special applications, slitting rewinders are also used to process metal foil materials, such as copper foil, aluminum foil, etc. The materials are also purchased in large rolls and then cut into smaller rolls as needed.

5. Medical Materials: In the medical industry, slitting rewinders are used to process medical materials, such as medical tapes, dressings, etc., which need to be rewound in a specific width and length for use in medical processes.

6. Other materials: In addition, the slitting rewinder can also be used to process some special materials, such as waterproof membrane, thermal insulation material, carbon fiber cloth, glass fiber cloth, etc., which have a wide range of applications in the construction industry, aerospace industry and other fields.

Overall, the slitter rewinder is suitable for a wide range of materials, covering almost all the rolls that need to be slitted and rewinded. However, the performance and accuracy requirements of different materials and industries for slitter rewinders may vary, so it is necessary to select the right model and configuration for specific needs in practical applications.

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026

It is not only production equipment, but also a key lever for enterprises to leverage profit growth by reducing costs, increasing efficiency and improving quality.

28. February, 2026

With the help of automation technology, significantly reduce manual intervention and usher in a new phase of cost reduction and efficiency improvement.

28. February, 2026

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026