There are many models of slitting machines, which can be divided into different types according to different classification standards. Here are some common slitter models and their features:

First, classification according to the cutting method

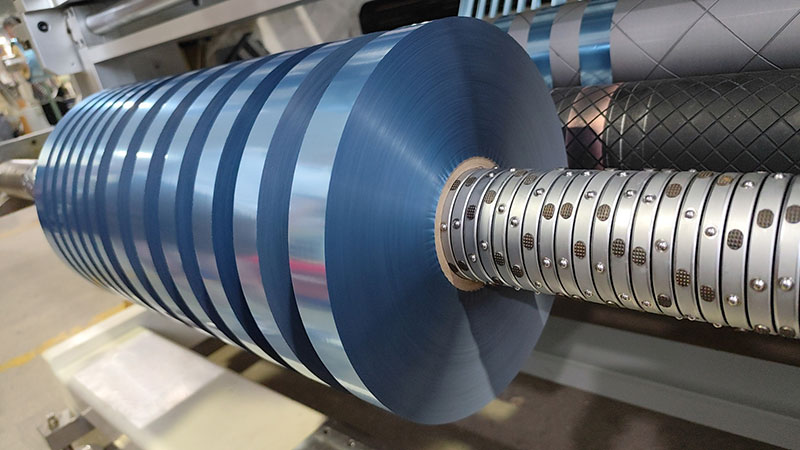

1. Slitting machine: mainly responsible for cutting large rolls of base metal along the longitudinal direction, suitable for slitting paper, film, aluminum foil and other materials.

2. Cross-cutting machine: Opposite to the slitting machine, the cross-cutting machine is to transversely cut the material that has been slitted into a narrow width to produce fixed-length sheets or small rolls.

3. Round knife slitting machine: It adopts a circular knife for high-speed rotary cutting, which is suitable for continuous high-speed cutting of thin and soft materials.

4. Flat Knife Slitting Machine: Use a straight edge flat knife, which is suitable for cutting thicker or harder materials.

5. Guillotine slitting machine: cutting by guillotine with reciprocating motion up and down, suitable for cutting a wide range of different materials.

Second, classification according to application fields

1. Paper slitting machine: specially used for paper slitting, with the characteristics of high efficiency and precision.

2. Film slitting machine: suitable for slitting of various film materials, such as PE, PET, PVC, etc.

3. Ribbon slitting machine: It is specially used for cutting and slitting ribbons, which is widely used in the printing industry.

4. Metal slitting machine: used for slitting of metal materials, such as steel plate, aluminum plate, etc.

Third, classification according to the degree of automation

1. Manual slitting machine: manual operation is required for slitting, suitable for small-scale production or experimental slitting.

2. Semi-automatic slitting machine: part of the operation is done automatically by the machine, and part needs manual intervention, which improves the production efficiency.

3. Automatic slitting machine: The whole slitting process is automatically completed by the machine, including feeding, positioning, cutting, winding and other steps, which greatly improves the production efficiency and cutting accuracy.

Fourth, the specific model example

1. High-speed slitting machine: specifications and models may include RSDS4, RSDS5, RSDS5 PLUS, RSDS6 PLUS, etc., with high-speed cutting, high-precision control and other characteristics.

2. Ultra-high speed slitting machine: RSDS8 PLUS, RSDS8H PLUS, suitable for slitting and rewinding all kinds of PET, BOPP, PVC, hot stamping foil, copper foil, aluminum foil and other materials.

It should be noted that the naming method of slitter models of different brands and manufacturers may be different, so when choosing a slitting machine, in addition to considering the model, you also need to pay attention to its performance parameters, scope of application, price, after-sales service and other factors. At the same time, with the continuous development of technology, new slitter models and technologies are constantly emerging, so it is advisable to fully understand the market dynamics and the latest technology trends when purchasing.

With the advancement of Industry 4.0, paper slitting machines are moving in the direction of smarter and more connected.

25. October, 2025

Before formulating a slitting plan, it is essential to fully understand the properties of each material and its impact on the slitting process.

23. September, 2025

Having advanced slitting equipment and technology is itself an endorsement of the strength of the enterprise.

23. September, 2025

After slitting, the physical state of the edge of the coil of hot stamping paper directly affects the subsequent processing and application.

23. September, 2025

As a key device for post-processing, the hot stamping paper slitting machine has seen a steady growth in market demand.

20. September, 2025