As a special equipment for processing hot stamping foil coils, the hot stamping foil slitting and rewinding machine has a series of distinctive features that enable it to play an efficient and precise role in the production process. The following are the main features of hot stamping foil slitting and rewinding machine:

1. High-precision slitting:

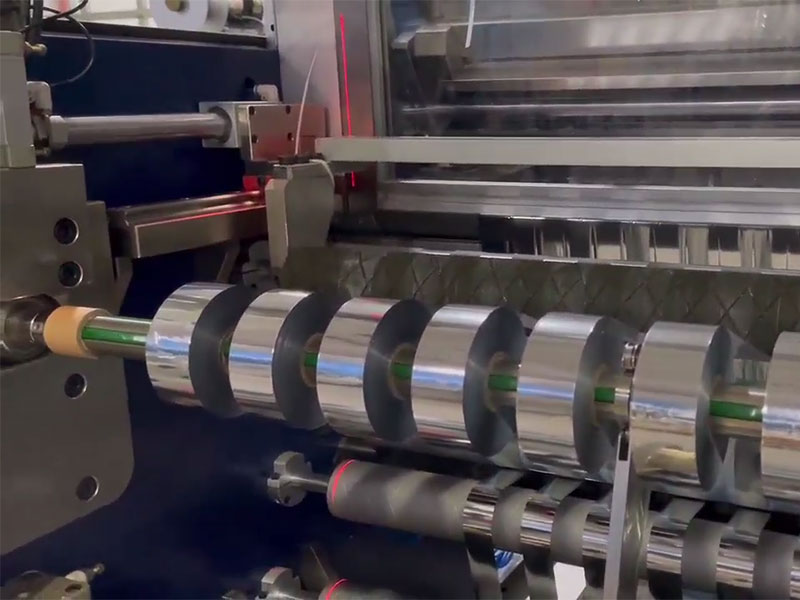

• The hot stamping foil slitting and rewinding machine is equipped with a high-precision slitting system, which can ensure that the edge of the slitting is flat and smooth, and the slitting size is accurate.

• With the help of advanced sensors and control systems, the equipment is able to monitor and adjust the slitting parameters in real time to adapt to different materials and thicknesses of hot stamping foil coils.

2. Efficient Automation:

• The equipment realizes automatic control, including the automatic loading, slitting, rewinding and unloading of coils, which reduces manual intervention and improves production efficiency.

• The automatic control system can automatically adjust the operating parameters of the equipment according to the preset program to ensure the stability and continuity of the production process.

3. Versatility:

• The hot stamping foil slitting and rewinding machine is not only suitable for slitting and rewinding hot stamping foil coils, but also can handle other similar coils.

• The equipment is usually equipped with a variety of slitting modes and rewinding modes, which can be selected and adjusted according to different production needs.

4. Easy to operate and maintain:

• The operating interface of the equipment is usually designed to be intuitive and easy to understand, so that the operator can get started quickly.

• Critical components and wear parts of the equipment are easy to disassemble and replace, reducing maintenance costs and time.

5. High Security:

• Hot stamping foil slitting and rewinding machines are designed with operator safety in mind, and are usually equipped with multiple safety protection devices.

• These devices can detect abnormal conditions in time during the operation of the equipment and take corresponding protective measures to ensure the safety of operators.

6. Energy saving and environmental protection:

• The equipment has low energy consumption and is designed with environmental factors in mind, reducing waste and pollutant emissions in the production process.

• Through the use of advanced materials and processes, the noise and vibration generated during the operation of the equipment are also effectively controlled.

7. Adaptable:

• Hot stamping foil slitting and rewinding machine can handle hot stamping foil coils of different specifications and thicknesses to meet different production needs.

• The equipment is also adaptable and flexible, which can be adjusted and optimized according to the actual situation of the production site.

To sum up, the hot stamping foil slitting and rewinding machine has the characteristics of high-precision slitting, efficient automation, versatility, easy operation and maintenance, high safety, energy saving and environmental protection, and strong adaptability. These characteristics make the equipment play an important role in the production and processing of hot stamping foil coils.

The leap in its core competitiveness stems from the comprehensive empowerment of intelligent control technology.

11. February, 2026

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026

a sophisticated system that combines mechanical engineering, materials science, and intelligent control.

11. February, 2026

hot stamping foil slitting machine, which is silently promoting the precision and efficiency of the entire industry as an "expert in customized slitting solutions".

09. February, 2026

the new generation of hot stamping foil slitting machine is moving towards the goal of "zero waste and precise slitting" through a series of innovative technologies.

09. February, 2026