As a special equipment for processing hot stamping foil coils, hot stamping foil slitting and rewinding machine has many advantages. Here are the main advantages of hot stamping foil slitting rewinder:

1. High-precision slitting:

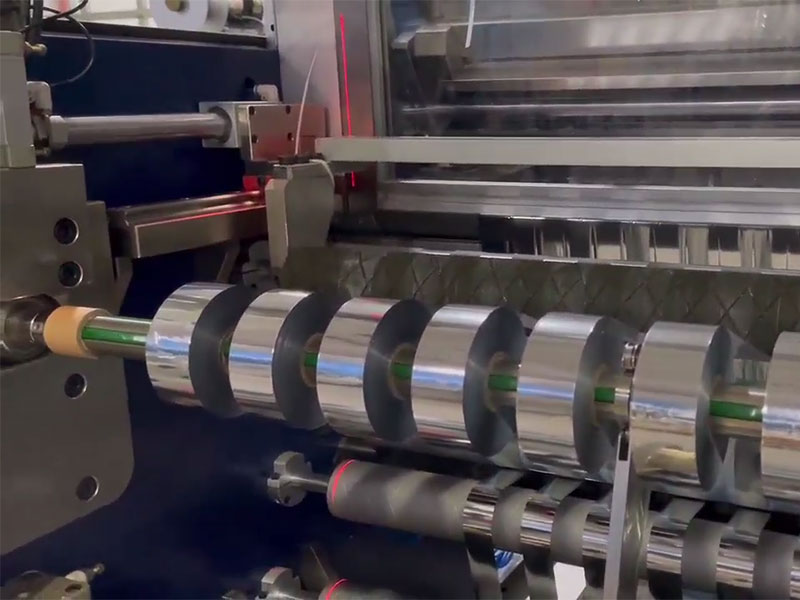

• Hot stamping foil slitting and rewinding machine adopts advanced slitting technology and high-precision control system, which can ensure the accuracy and efficiency of slitting. Whether longitudinal or transverse slitting, high dimensional accuracy and edge quality can be achieved.

2. Efficient Automation:

• The equipment is usually equipped with an automatic control system, which can realize the automatic production of the whole process of coil feeding, slitting, rewinding and unloading. This greatly improves production efficiency, reduces manual intervention, and lowers production costs.

3. Versatility:

• Hot stamping foil slitting and rewinding machine is not only suitable for slitting and rewinding hot stamping foil coils, but also can process other similar materials of coils, such as PET, metal foil, etc. This increases the range and flexibility of the equipment.

4. Easy to operate and maintain:

• The operating interface of the equipment is usually designed to be intuitive and easy to understand, so that the operator can get started quickly. At the same time, key components and wear parts are easy to disassemble and replace, reducing maintenance costs and time.

5. High Security:

• Hot stamping foil slitting and rewinding machines are designed with operator safety in mind, and are usually equipped with multiple safety protection devices. These devices can detect abnormal conditions in time during the operation of the equipment and take corresponding protective measures to ensure the safety of operators.

6. Adaptable:

• The equipment is capable of processing hot stamping foil coils of different specifications and thicknesses to meet different production needs. At the same time, by adjusting the parameters and settings of the equipment, it can adapt to coil processing of different materials and uses.

7. Energy saving and environmental protection:

• The hot stamping foil slitting and rewinding machine is designed with energy saving and environmental protection, and adopts advanced energy-saving technology and materials. This helps to reduce the energy consumption and emissions of the equipment, reducing the environmental impact.

8. Improve product quality:

• Due to the characteristics of high-precision slitting and efficient automation, the processed hot stamping foil coils can be guaranteed to be of high quality and consistency. This helps to improve the market competitiveness of the product.

To sum up, the hot stamping foil slitting and rewinding machine has many advantages such as high-precision slitting, efficient automation, versatility, easy operation and maintenance, high safety, strong adaptability, energy saving and environmental protection, and improved product quality. These advantages make the equipment have a wide range of application prospects in the field of processing and handling of hot stamping foil coils.

The leap in its core competitiveness stems from the comprehensive empowerment of intelligent control technology.

11. February, 2026

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026

a sophisticated system that combines mechanical engineering, materials science, and intelligent control.

11. February, 2026

hot stamping foil slitting machine, which is silently promoting the precision and efficiency of the entire industry as an "expert in customized slitting solutions".

09. February, 2026

the new generation of hot stamping foil slitting machine is moving towards the goal of "zero waste and precise slitting" through a series of innovative technologies.

09. February, 2026