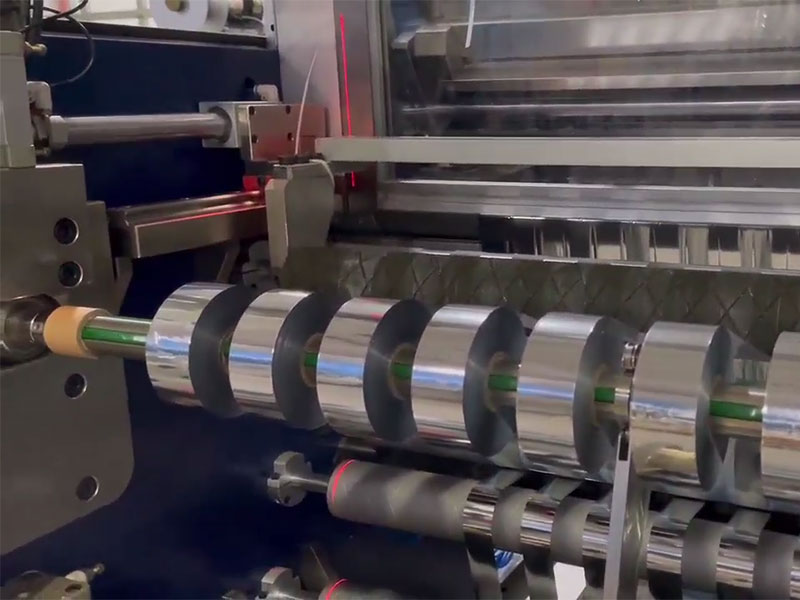

Hot stamping foil slitting machine is a precision equipment used for hot stamping material processing, which is mainly used to cut large rolls of hot stamping foil materials into small rolls of required width to meet the needs of different hot stamping processes. Here are its key features and applications:

Key features:

1. High-precision slitting

◦ Precision tools and control systems are used to ensure that the slitting width error is very small and meet the requirements of high precision.

2. Automate operations

◦ Equipped with automatic tension control, web correction and winding system to reduce manual intervention and improve efficiency.

3. Efficient production

◦ High-speed slitting, suitable for mass production, significantly improving processing efficiency.

4. Versatility

◦ It can handle hot stamping foil materials of different thicknesses and widths, and can adapt to a variety of hot stamping needs.

5. Stability and durability

◦ The structure is sturdy, and the key components are made of wear-resistant materials to ensure long-term stable operation.

Main applications:

1. Packaging industry

◦ It is used for the cutting of bronzing materials for high-end packaging such as cigarette packs, wine bags, gift boxes, etc.

2. Printing industry

◦ It is used for the processing of hot stamping materials for book covers, posters and other printed materials.

3. Label industry

◦ It is used for the slitting of hot stamping materials for high-grade labels to improve the product grade.

4. Decoration industry

◦ It is used for the processing of hot stamping materials for surface decoration such as furniture and electronic products.

Procedure

1. Feeding

◦ Install the large coil of hot stamping foil material to the unwinding unit.

2. Set the parameters

◦ Set slitting width, tension and other parameters according to requirements.

3. Slitting

◦ Start the machine to complete the slitting and winding automatically.

4. Quality inspection

◦ Check whether the material after slitting meets the requirements.

5. Packaging

◦ Qualified products are packed and put into storage.

Maintenance & Maintenance

1. Clean regularly

◦ Keep the device clean and prevent dust from affecting accuracy.

2. Lubrication and maintenance

◦ Lubricate moving parts regularly to reduce wear.

3. Check the knives

◦ Regularly check the wear and tear of the knives and replace them in time.

4. System calibration

◦ Calibrate the control system regularly to ensure accuracy.

summary

Hot stamping foil slitting machine is a key equipment in the processing of hot stamping materials, which is widely used in packaging, printing, labeling and decoration industries with high precision, automation and high efficiency. Proper operation and maintenance can ensure the long-term stable operation of the equipment and improve production efficiency.

The leap in its core competitiveness stems from the comprehensive empowerment of intelligent control technology.

11. February, 2026

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026

a sophisticated system that combines mechanical engineering, materials science, and intelligent control.

11. February, 2026

hot stamping foil slitting machine, which is silently promoting the precision and efficiency of the entire industry as an "expert in customized slitting solutions".

09. February, 2026

the new generation of hot stamping foil slitting machine is moving towards the goal of "zero waste and precise slitting" through a series of innovative technologies.

09. February, 2026