In order to achieve efficient slitting of multi-material compatible slitting machines, it is necessary to break through the limitations of single material adaptation of traditional equipment, and realize one-machine slitting of heterogeneous materials such as film/metal foil/non-woven fabric through modular design, intelligent sensing and dynamic control system. The following are the key technical solutions and implementation paths:

1. Core Challenges & Design Principles

| Material properties | Slitting difficulty | Resolution direction |

| Film (PET/PP) | Easy stretching, electrostatic adsorption | Ultra-low tension control (<5N) |

| Metal Foil (Cu/Al) | High hardness, burr control | High Frequency Vibrating Tools (20-40kHz) |

| Non-woven fabrics | Fibers scatter and edges are delineated | Negative pressure adsorption + ultrasonic edge banding |

• Modular: Quick change of tension/tool/winding module (changeover time < 3 minutes)

• Wide parameter range: tension range 0.1-200N, speed 5-800m/min adjustable

• Material Fingerprint Library: 100+ material process parameter packages are pre-stored

2. Innovative design of key subsystems

(1) Intelligent tension control system

• Three-mode tension adjustment:

◦ Film: Magnetic particle brake + air flotation roller (fluctuating ± 0.5N)

◦ Foil: servo motor + tension arm (constant tension ±1%)

◦ Non-woven fabric: constant torque winding + dancer roll compensation

• AI real-time prediction: LSTM model presets tension based on sudden changes in material thickness (response time 8ms)

(2) Compound cutting unit

| Cutting method | Applicable Materials | Technical parameters |

| Round knife shear | Metal foil / thick non-woven fabric | Tool clearance 0.1-0.3mm (automatic adjustment) |

| Air-levitated laser | Ultra-thin film (< 10μm) | The spot diameter is 15μm, and the power is adjustable from 0-200W |

| Ultrasonic knife | Nonwoven/composite | The frequency is 28kHz, and the amplitude is 5-50μm |

(3) Adaptive winding system

• Multi-station winding: 12 stations with independent drive, supporting:

◦ Film: Center take-up (air pressure 0.1MPa)

◦ Foils: Surface Take-up (Pressure Gradient Control)

◦ Non-woven fabric: tower winding (anti-stacking)

• Intelligent taper calculation: Automatically generate a pressure curve based on the elastic modulus of the material

3. Intelligent perception and decision-making system

(1) Multi-modal detection system

• Hyperspectral camera (400-2500nm): Identification of material type (99.3% accuracy)

• Laser thickness gauge: 0.1μm resolution, closed-loop control of tool clearance

• Acoustic emission sensor: monitoring of tool wear status (early warning accuracy ±5%)

(2) Dynamic process engine

4. Comparison of parameters in typical slitting scenarios

| parameter | 6 μm copper foil | 20 μm PET film | 50gsm non woven fabric |

| Slitting speed | 80-120m/min | 300-500m/min | 150-200m/min |

| Tension control | 15±0.5N | 2±0.1N | 8±1N |

| The type of tool | Diamond-coated knives | Air plasma knives | Ultrasonic knife |

| Rewinding pressure | Linearity 0.3→0.1MPa | Constant 0.05MPa | Stepped 0.2→0.08MPa |

5. Economic benefits and industry value

• Changeover efficiency: shortened from 4 hours to 8 minutes (30 times faster)

• Loss control: comprehensive loss rate < 0.8% (metal foil 1.2% → 0.5%, film 0.6% → 0.2%)

• Application Scenarios:

◦ New energy: pole piece/diaphragm slitting machine

◦ Medical: Composite slitting of non-woven fabrics and medical films for protective clothing

◦ Packing: Precise slitting of aluminum-plastic composite film

Future Evolution Direction

• Self-learning material library: automatic generation of new material process parameters from a small number of samples (small sample learning technology)

• Digital Twin Rehearsal: 100% slitting testing in a virtual environment before physical execution

• Green slitting: laser cutting replaces mechanical knives, reducing metal foil slitting dust by 90%

Through this design, the multi-material compatible slitting machine can reduce the equipment investment cost by 40% (compared with multiple special equipment), and at the same time meet the needs of flexible production, becoming the core equipment of the smart factory.

choosing a professional PET film slitting machine is no longer a luxury option but a necessity to remain competitive.

06. February, 2026

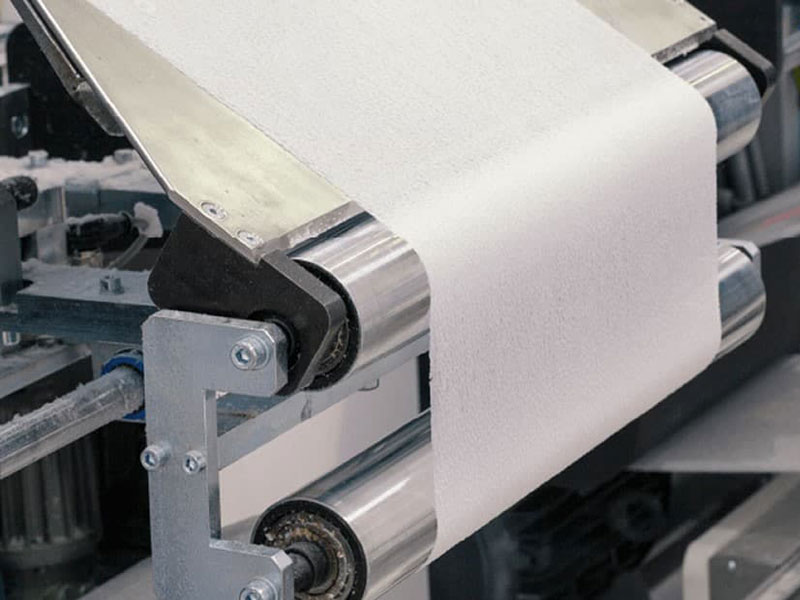

It slits wide film into narrow rolls of various specific widths, and its technical level directly determines the quality and production efficiency of the end product.

06. February, 2026

This article will delve into how advanced automotive film slitting machines can help businesses achieve their goal of doubling production capacity.

04. February, 2026

High tension control does not exist in isolation and needs to work in tandem with other innovative systems of the slitting machine to achieve the best results.

02. February, 2026

The bottleneck of cumbersome and slow response in the traditional slitting mode is becoming increasingly prominent.

30. January, 2026