To increase the production efficiency of solar film slitting machine by 300%, systematic improvements need to be made from various aspects such as equipment upgrades, process optimization, automation and personnel management. Here's a high-return cutting solution, step-by-step:

1. Equipment upgrades: core hardware transformations

• High-speed servo motor replaces traditional motor

High-precision servo systems (such as Siemens Germany) are used to increase the cutting speed from the traditional 20-30 m/min to 80-100 m/min while maintaining an accuracy of ± 0.1mm.

• Multi-head synchronous cutting technology

Install parallel multi-tool heads (such as 4-6 sets of inserts), and control them synchronously through the CNC system to slice multiple rolls of material at one time, and the efficiency is directly increased by 3-4 times.

• Laser or ultrasonic cutting instead of mechanical knives

Reduce material deformation and downtime due to physical contact, increase cutting speed by more than 50%, and have a longer life.

2. Intelligent control system

• Dynamic visual positioning system

Industrial cameras (such as Keyence) are installed to identify material edges and defects in real time, automatically adjust the cutting path, reduce manual calibration time, and increase the yield rate to more than 99%.

• Internet of Things (IoT) remote monitoring

Predictive maintenance reduces unplanned downtime by 30% by collecting equipment operating data (e.g., temperature, vibration, blade wear) through sensors.

3. Process optimization: Reduce invalidity time

• Automatic docking technology for coils

With the unwinding system, the old and new coils are automatically bonded without stopping, saving 15-20 minutes of downtime for each rewinding change.

• Intelligent scheduling algorithm

Automatically optimize cutting solutions (e.g. nesting layout) according to order demand, increase material utilization from 85% to 95%, and reduce waste directly and reduce costs.

4. Automated logistics connection

• AGV automatically handles finished products

The slitted coils are automatically transported to the packaging area by AGV trolleys, reducing manual handling time and increasing the overall process efficiency by 20%.

• Automatic palletizing by robotic arm

With the end effector, the finished product is automatically stacked, and the packaging efficiency is increased by 200%.

5. Personnel training and performance management

• Standardized operation training

Through VR simulation equipment operation, the onboarding time for new employees is shortened to 1 week.

• KPI dynamic incentives

Linking production efficiency to bonuses (such as 300% increase in output per unit of time, rewarding 15% performance) significantly increases employee motivation.

Return on investment measurement

• Cost investment: about 50-800,000 yuan for equipment upgrades and 200,000 yuan for automation systems.

• Increased revenue:

◦ Daily output increased from 1000 rolls to 4000 rolls (300% increase);

◦ Waste reduction saves about 300,000 yuan in material costs per year;

◦ Labor costs are reduced by 40%.

• Payback period: 6-12 months (based on medium-sized factory size).

Key success factors

• Choose a modular upgrade solution to avoid the high cost of complete machine replacement;

• Joint development of customized control systems with equipment manufacturers;

• Pilot verification and then comprehensive promotion to reduce risks.

Through the above technologies and management optimizations, a 300% efficiency increase in solar film slitting machines is fully achievable, and the return on investment (ROI) is significantly higher than that of traditional retrofitting methods.

With the help of automation technology, significantly reduce manual intervention and usher in a new phase of cost reduction and efficiency improvement.

28. February, 2026

This article will delve into how advanced automotive film slitting machines can help businesses achieve their goal of doubling production capacity.

04. February, 2026

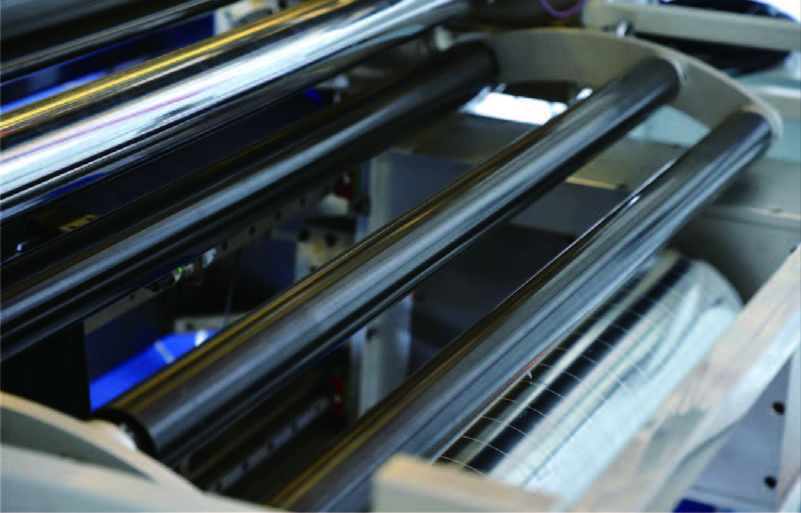

These film materials need to be precisely cut into different widths during the production process to meet the needs of various models and components.

10. December, 2025

The automotive film slitting machine, an increasingly intelligent "cutting knife", is accurately cutting out redundant costs, inefficient processes and backward production methods.

10. December, 2025

It cuts wide raw film rolls into various sizes required by customers with millimeter-level accuracy.

02. December, 2025