By improving the slitting efficiency, accuracy, and automation level, the solar film slitting machine significantly shortens the delivery cycle of enterprises, and its core role and specific implementation methods are as follows:

1. High-speed slitting directly increases production capacity

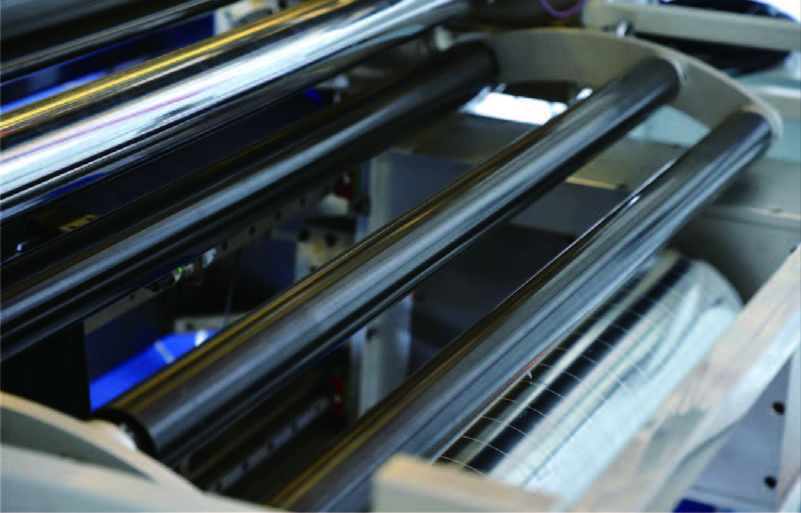

• High speed design: Modern slitting machines use servo motors and precision transmission systems, and the cutting speed can reach 100-300 m/min (traditional equipment is about 30-80 m/min), and the output per unit time is increased by more than 3 times.

• Continuous operation: The automatic unwinding/unwinding system supports 24-hour uninterrupted production, reducing downtime and is especially suitable for urgent orders.

2. Intelligent optimization to reduce preparation time

• One-click parameter setting: Store historical order data (such as width, tension, etc.), no need for manual debugging when switching products, and shorten the preparation time from 30 minutes to less than 1 minute.

• Visual Positioning System: Automatically identify material edges and defects, reducing manual alignment and quality inspection time.

3. Precise slitting to reduce scrap rate

• ±0.1mm Accuracy: Laser or CNC tool heads ensure no deviations in slitting, and scrap rates are reduced from 5% to less than 0.5%, reducing rework and material waste.

• Dynamic tension control: adjust the tension in real time to avoid film stretching and deformation, and ensure the yield rate.

4. Automation integration to compress process gaps

• Inline production: Directly connected with the coating machine and rewinder, eliminating the need for intermediate handling and waiting, and reducing the overall process time by 40%.

• Automatic sorting and packaging: automatic labeling and palletizing after slitting, increasing the efficiency of the packaging process by 50%.

5. Data-driven, optimized production scheduling

• MES system docking: real-time monitoring of equipment status and order progress, intelligent production scheduling prioritizes urgent orders, and increases the controllability of delivery cycle by 60%.

Practical case

After the introduction of a high-speed slitting machine in an automobile film manufacturer:

• Increasing production capacity from 5,000 meters to 15,000 meters per day;

• Delivery time reduced from 7 days to 2 days;

• Labor costs reduced by 30%.

summary

The solar film slitting machine helps enterprises quickly respond to orders through the three cores of speed improvement, intelligent consumption reduction, and process integration, especially suitable for customized and multi-batch small orders and quick reaction needs, and has become a key efficiency lever in the highly competitive film processing industry.

With the help of automation technology, significantly reduce manual intervention and usher in a new phase of cost reduction and efficiency improvement.

28. February, 2026

This article will delve into how advanced automotive film slitting machines can help businesses achieve their goal of doubling production capacity.

04. February, 2026

These film materials need to be precisely cut into different widths during the production process to meet the needs of various models and components.

10. December, 2025

The automotive film slitting machine, an increasingly intelligent "cutting knife", is accurately cutting out redundant costs, inefficient processes and backward production methods.

10. December, 2025

It cuts wide raw film rolls into various sizes required by customers with millimeter-level accuracy.

02. December, 2025