In the world of boutique packaging, the first thing we often feel is the visual impact: the luxury of hot stamping, the texture of embossing, and the precision of color. However, behind these glamorous visual arts lies a crucial but often overlooked process, which is the starting point and cornerstone of all beautiful packaging – cardboard slitting. And it is the silent craftsman of modern industry that performs this critical task: the cardboard slitter.

From coil to substrate: the precise "first knife"

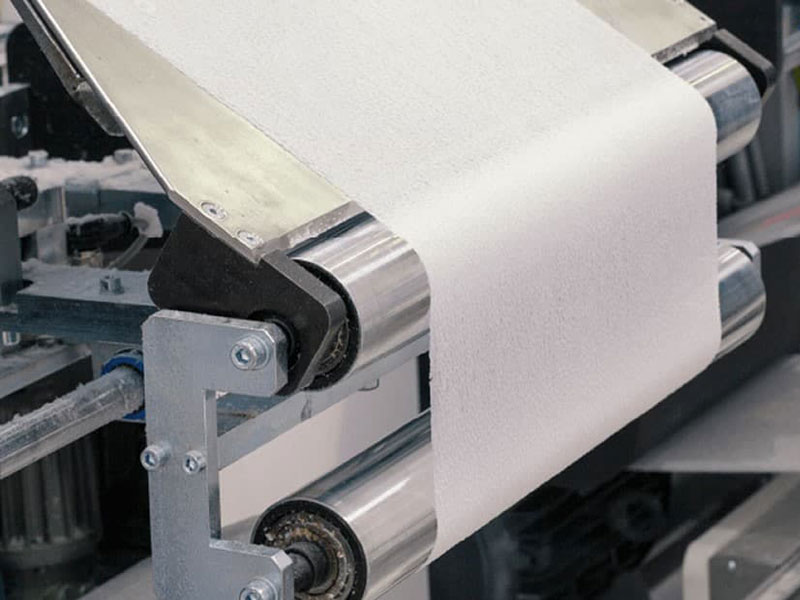

The journey of boutique packaging begins with a flat, crisp cardboard. These cardboards originally appeared in huge rolls, like a gorgeous piece of fabric waiting to be cut. The primary mission of the cardboard slitting machine is to cut this huge coil into semi-finished products of a specified width through high-precision cutting, rolling or slitting.

This step seems simple, but it actually hides the universe. The accuracy of slitting directly determines the success or failure of all subsequent processes such as printing, die-cutting, and folder gluing. Even a deviation of just a millimeter can lead to inaccurate printing sleeves, rough die-cut edges, and ultimately defective packaging products. A high-performance jam slitting machine, with its stable tension control system, scalpel-sharp cutter and intelligent correction device, ensures that each roll and every sheet of jammed paper is accurately sized and the edges are smooth and flat, laying a solid and reliable foundation for subsequent gorgeous transformations.

"Tailoring" for efficiency and cost

In the highly competitive packaging industry, efficiency and cost control are the lifelines of enterprises. The jam slitter plays the dual role of "actuary" and "efficiency expert" here.

• Reduce waste and make the most of it: By optimizing the tool rowing scheme, the slitting machine maximizes the use of raw materials and minimizes leftovers. This is particularly significant in the face of expensive special paper and art paper. Every millimeter of savings is to increase the competitiveness of the product.

• Improve overall production efficiency: Cut cardboard rolls or flat sheets can be seamlessly connected to high-speed printing machines and automated production lines. This avoids downtime due to waiting or adjustment of subsequent equipment, making the entire production process as smooth as a cloud. Without the efficient "material preparation" of the slitting machine at the front end, there is no way to talk about the "finishing" of the back end.

Guardians of Quality: More than size

An excellent cardboard slitting machine protects not only the accuracy of the size, but also the quality of the paper itself.

• Dust-free and clean: Modern slitting machines are equipped with dust removal systems that effectively remove paper dust and impurities during the slitting process, ensuring that the paper jammed surface is as smooth as new. This is crucial for extremely demanding processes such as UV printing and lamination, where even a tiny speck of dust can create a dazzling blemish on the finished product.

• Protect the material: Precise tension control avoids the deformation of the paper being stretched or squeezed during high-speed slitting, especially for special materials such as transfer laser paper and tactile paper, which are easily damaged.

On the cornerstone, it blooms

When we hold a luxury gift box with exquisite design and workmanship, we marvel at the designer's ingenuity and printing craftsmanship. But don't forget that the starting point of all this splendor is the impeccably cut cardboard. It is the "silent cornerstone" of the slitting machine that carries all subsequent artistic creations.

Although it is behind the scenes and does not directly participate in the final visual presentation, it uses steel precision and intelligent control to provide the perfect canvas for creativity. From mobile phone boxes, cosmetic gift boxes to high-end wine boxes, and health product packaging, behind every piece of high-quality packaging that people can't put down, there is a silent figure of cardboard slitting machines.

Conclusion:

Card paper slitting machine, the basic equipment in the packaging industry chain, has truly become the cornerstone of high-quality packaging with its indispensable precision, efficiency and quality protection. It reminds us that the ultimate luxury comes from the ultimate pursuit of every basic link. Today, when the art of packaging continues to move to new heights, the "silent craftsman" of the cardboard slitting machine will continue to hold up more creativity and beauty with its solid and reliable arms.

Differential shafts and inflatable shafts are often used as winding or unwinding shafts in the production process of slitter machines. After the

13. November, 2023

The tension of the slitting machine is an important factor in controlling the slitting results of the product, which is very helpful for the running speed, uniformity and stability, so special attenti

31. August, 2023

There are some details that need to be paid attention to during production to avoid accidents.

01. August, 2024

In the process of slitting processing using the slitting machine, the problem of rewinding failure is sometimes encountered, which is mainly manifested as bumps, uneven tightness, unequal rewinding an

30. August, 2023

Slitting machine is mostly used in papermaking machinery and printing and packaging machinery, common slitting machines

23. September, 2023