Today, we are redefining the standards of the industry with impeccable and reliable quality.

05. November, 2025

With its extremely precise "cutting" process, it is silently cutting out a clear and solid path for the future of the new energy industry.

05. November, 2025

It will continue to empower the future with faster speeds, more accurate cutting, and smarter handling, driving the world to run more efficiently and accurately.

04. November, 2025

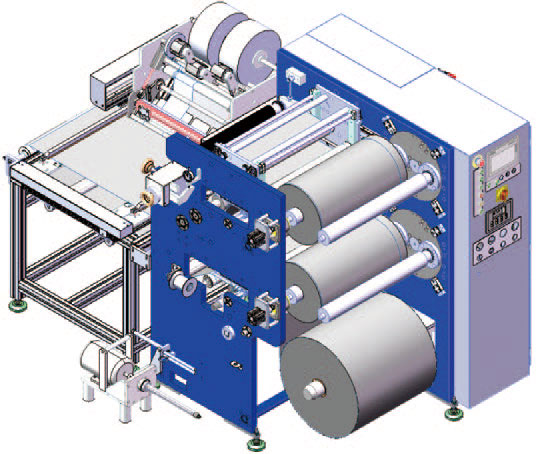

the ribbon slitting machine stands firmly at the key node of the ribbon industry chain with its core value of "efficient slitting and accuracy".

04. November, 2025

The ribbon slitting machine, with its professional attitude, provides precise conversion solutions from macro master rolls to micro applications.

04. November, 2025

In an increasingly competitive market environment, whoever masters advanced productivity first will occupy the high ground of value.

03. November, 2025

A high-performance slitting machine, its "refinement" is not only reflected in quality, but also in efficiency.

03. November, 2025

An excellent hot stamping foil slitting machine is the core equipment that casts this "precision blade".

03. November, 2025

countless wide master coil materials can be transformed into specific sizes that meet the terminal needs through its precise cutting and flow into thousands of households.

01. November, 2025

The prelude to a new era has begun, and it is these silent but powerful core technical forces that drive it.

01. November, 2025