This is not only a technological innovation, but also a profound change in production concepts.

28. October, 2025

It is not only a machine, but also a tailor of light and shadow, a forger of brand charm, and it is it that makes every packaging "shine" outstanding.

28. October, 2025

Label slitting machine: how to achieve the precise operation of "pointing and hitting where"?

28. October, 2025

Equipment for high-speed, high-precision slitting of wide metal strips (such as aluminum strips, nickel strips, or copper-aluminum composite strips) into the required width and number of tabs.

27. October, 2025

are precision equipment specifically designed to slice wide optical film materials into predetermined widths.

27. October, 2025

The value of this "unmistakable" slitting is far more than the improvement of the yield. It directly empowers downstream industries:

27. October, 2025

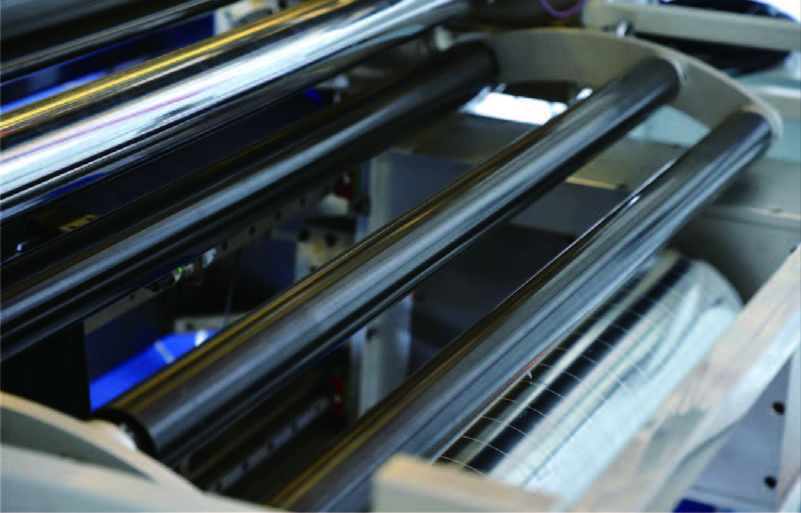

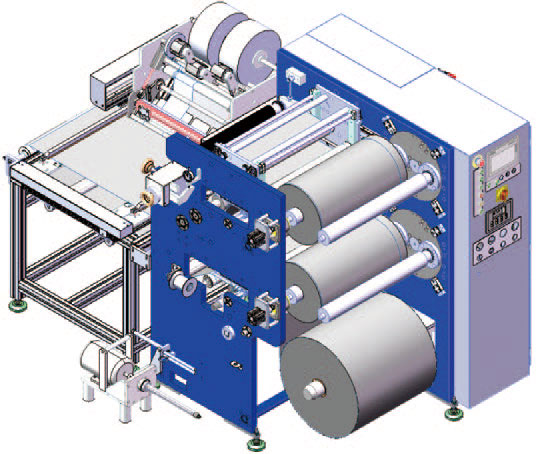

is a kind of equipment that slices wide film or thin material rolls into multiple narrow strips of material at high speed and high precision according to the process requirements.

25. October, 2025

Behind this, the composite slitting machine plays an indispensable cornerstone role with its ultimate pursuit of "precision".

25. October, 2025

With the advancement of Industry 4.0, paper slitting machines are moving in the direction of smarter and more connected.

25. October, 2025

The hot stamping foil slitting machine is no longer a simple auxiliary equipment, but one of the core links for enterprises to achieve lean production and move towards intelligent manufacturing.

24. October, 2025