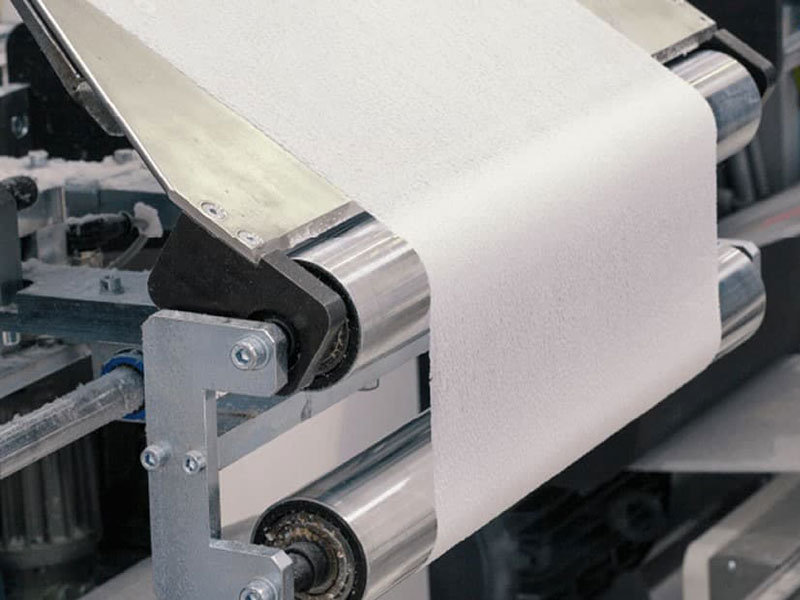

Every time you slit, it is not only dividing materials, but also delineating a new starting line for the tomorrow of the high-tech industry.

21. October, 2025

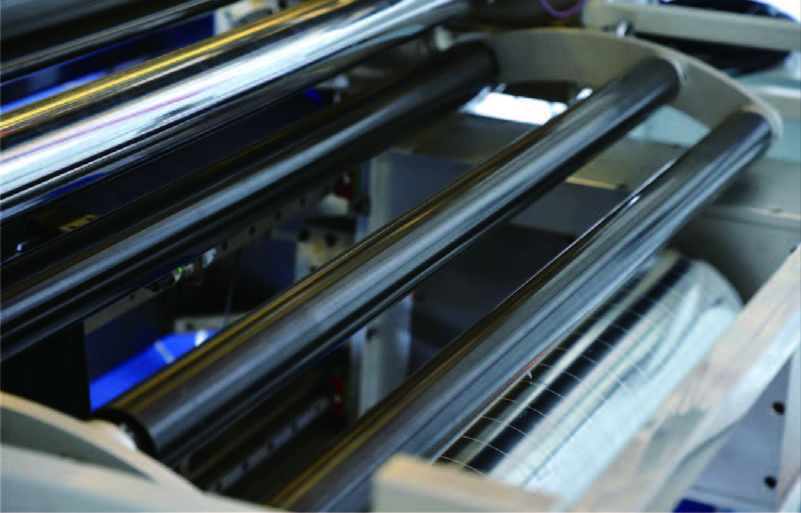

Precision processing, comparable to 'surgical operations,' carried out by the sophisticated 'graphite film slitting machine.'

20. October, 2025

the soul of a truly excellent film slitting machine lies in the ultimate reliability tempered by "Seiko Intelligent Manufacturing".

20. October, 2025

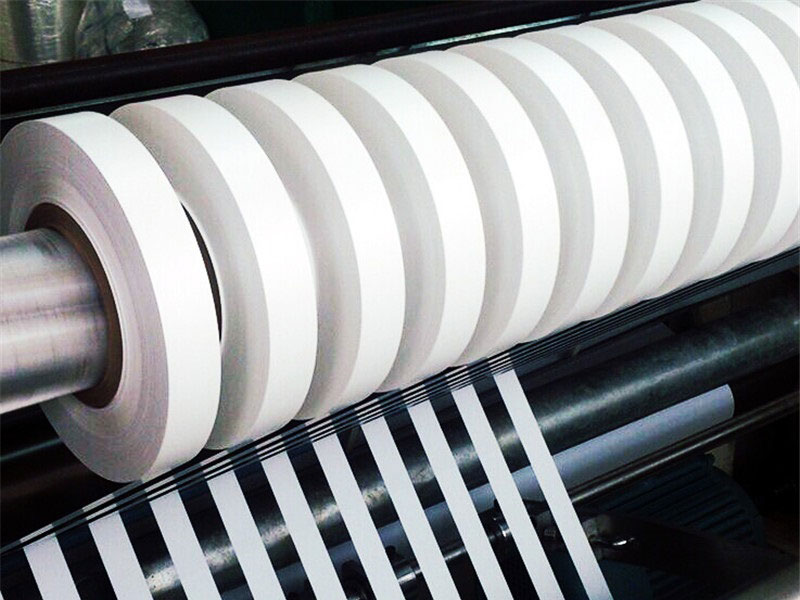

Its mission is to cut wide master roll material into countless narrow rolls or single labels of consistent specifications according to preset sizes.

20. October, 2025

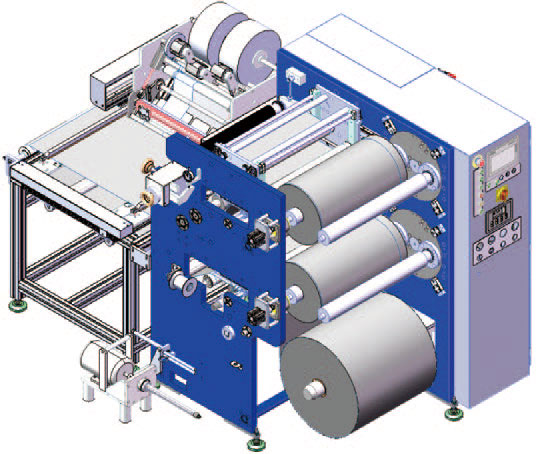

It symbolizes a new industrial philosophy: leaving certainty to data and algorithms, and leaving creativity to humans.

18. October, 2025

at the heart of the process of transforming huge master rolls into a dazzling array of small finished rolls, the tape slitting machine

18. October, 2025

It reminds us that the ultimate luxury comes from the ultimate pursuit of every basic link.

18. October, 2025

It is that, with millimeter or even micron-level accuracy, has laid a solid and reliable foundation for the stability and innovation of the entire electronics industry.

17. October, 2025

Among them, a seemingly inconspicuous but crucial link, pole piece slitting, is quietly determining the performance and fate of the battery with its "millimeter difference".

17. October, 2025

According to the design requirements of the battery cell, cut it into multiple narrow strips with consistent width, neat edges, and no burrs.

17. October, 2025