With the continuous expansion of the market for electric vehicles, portable electronic devices, etc., the demand for lithium batteries is also increasing. In the production process of lithium batteries, slitting is a very critical step. Therefore, the development prospect of lithium battery slitting machine is also very broad.

The following are several aspects of the development prospect of lithium battery slitting machine:

Technology upgrading: With the continuous progress of science and technology, the technology of lithium battery slitting machine is also constantly upgrading, which can be slitting more accurately, improve production efficiency, reduce energy waste and scrap rate, and also reduce the labor intensity of workers.

Market demand: With the rapid development of electric vehicles, smartphones, tablets and other markets, the demand for lithium batteries is also increasing. This will further drive the demand and development of lithium battery slitting machines.

Environmental awareness: The improvement of environmental awareness in modern society has also promoted the development of lithium battery slitting machines. Lithium battery slitting machine can reduce the number of waste lithium batteries, thereby reducing pollution to the environment.

Automated production: The lithium battery slitting machine can cooperate with other equipment to realize the construction of automated production lines, improve production efficiency and quality, and reduce labor costs and management difficulties.

Therefore, with the continuous progress of technology and the increasing market demand, the development prospect of lithium battery slitting machine is very broad.

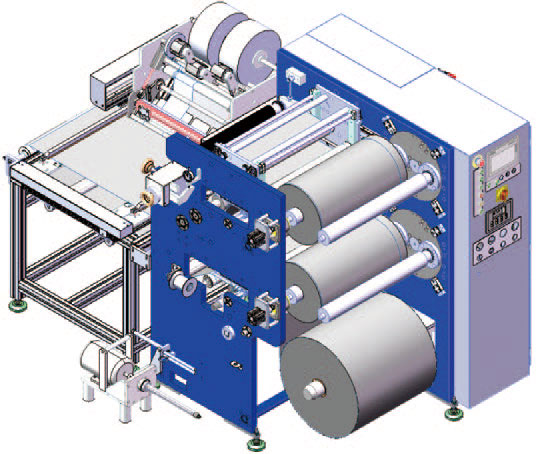

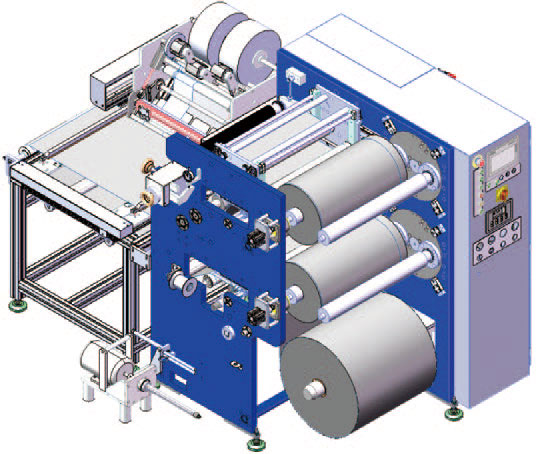

Equipment for high-speed, high-precision slitting of wide metal strips (such as aluminum strips, nickel strips, or copper-aluminum composite strips) into the required width and number of tabs.

27. October, 2025

According to the design requirements of the battery cell, cut it into multiple narrow strips with consistent width, neat edges, and no burrs.

17. October, 2025

This is achieved through a system engineering that combines mechanical engineering, materials science, automatic control and sensing technology.

12. September, 2025

The technical level of the slitting machine directly determines the yield, quality consistency of the separator, and the safety and performance of the final battery.

27. August, 2025

Below I will elaborate on how to improve cutting quality through parameter optimization from three aspects: core parameters, optimization strategies, and systematic methods.

22. August, 2025