The factors affecting the output torque of the winding shaft of the slitting machine are studied, and the ideal values of the input pressure and the output torque are determined by the methods of theoretical analysis and experimental verification, which provides a basis for the design and application of the slitting machine, and has certain theoretical and practical application value.

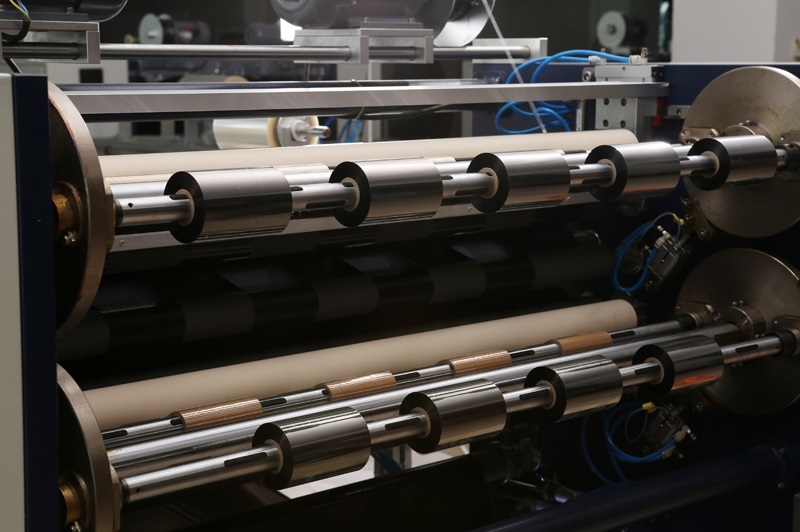

The function of the winding shaft of the slitting machine is to wind various materials after slitting into multi-roll roll materials on one shaft, and the size and consistency of the winding moment of the winding shaft determine the winding quality. According to the applicable materials, film width, minimum slitting width, coil diameter and other parameters of the slitting machine, the output torque range and accuracy requirements of each slip ring are obtained, which provides a basis for determining the parameters of the slip axis.

The slitting machine winding shaft conducts theoretical qualitative analysis and experimental verification of the relationship between the surface roughness of the slip ring and the friction torque, and determines the roughness suitable for the material of the slip ring to achieve the ideal working condition. The material type of the slip bond is determined by theoretical analysis. The experimental verification method is used to determine the optimal formula of slip bond material, retain the good high and low temperature resistance, corrosion resistance, self-lubrication, non-stick and other characteristics of PTFE, improve its mechanical properties of non-wear-resistant, low hardness and easy cold flow, meet the requirements of stable and consistent output torque and wear-resistant of slip key, and ensure the consistency of product quality. According to the requirements of the actual work, through the linearization of the performance curve, the actual value of the input pressure and the output torque of the slip shaft is close to the theoretical value, so as to achieve the required accuracy and ensure the quality of the winding.

Slitting, this seemingly simple action, is actually the ultimate pursuit of precision.

03. March, 2026

They will be shipped to cigarette packaging factories, wine box factories, gift wrapping companies, and finally become those memorable and beautiful packaging in our hands.

03. March, 2026

Every micron-level improvement in slitting accuracy, every percentage decrease in scrap rate, is a scale of industry progress.

03. March, 2026

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026