As an important helper in the production of enterprises, the rewinder can be said to have a good application in many industries, so what are the components of the rewinder in general? Let's take a look at it with the rewinder manufacturer.

1. Product bending method:

The board debugs the pneumatic shaft, which can quickly put on and place the paper tube, which is suitable for the data with a more stable thickness.

2. The curling power part of the rewinder:

The curl tension is bent by clutch slip, which is delicate and easy to adjust.

3. Motor control part:

The length control part uses a photoelectric sensor and a two-stage length counter, and the length is accurate. The tension manipulator is actively wound and can actively increase the tension with the change of diameter. Fundamental discharging method: continuous discharging machine base, easy to operate, small floor space.

4. Curling mechanical part:

This machine can also be equipped with an optional continuous transmission bend to cut other materials more extensively. The curling method is used as both the center and the exterior, and you can freely choose to use it when rewinding different materials. The crimping shaft is combined with pressure transmission and bending, which can be pressed out of the air in the curling river, so that the product is tighter and has a more textured appearance.

As an important part of the rewinder, the above four parts can be said to have been widely used and liked by people.

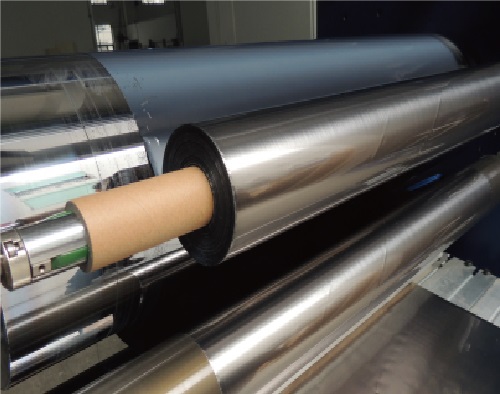

The stable operation of the slitting rewinder is the basis for producing high-quality coil products.

10. December, 2025

Precisely cut the wide master roll according to the preset dimensions, then rewind it into finished rolls suitable for subsequent processing or direct use.

09. December, 2025

Cut wide rolls of film, paper, nonwoven fabric, metal foil, and other materials to precise sizes, and then rewind them into finished rolls that meet downstream requirements.

09. December, 2025

A slitting rewinder is a device that slices wide coils into multiple narrow strips of material and rewinds them into independent rolls.

09. December, 2025

A suitable slitting and rewinding machine can not only greatly improve production efficiency, but also reduce material loss and ensure product quality.

08. December, 2025