1. The mechanical safety device must be used correctly according to the regulations, and it cannot be removed or not used.

2. When the equipment of the paper tube cutting machine is running, it is strictly forbidden to adjust it by hand; It is also forbidden to measure parts by hand, lubricate, clean debris, etc. If it is necessary, the machinery should be shut down first.

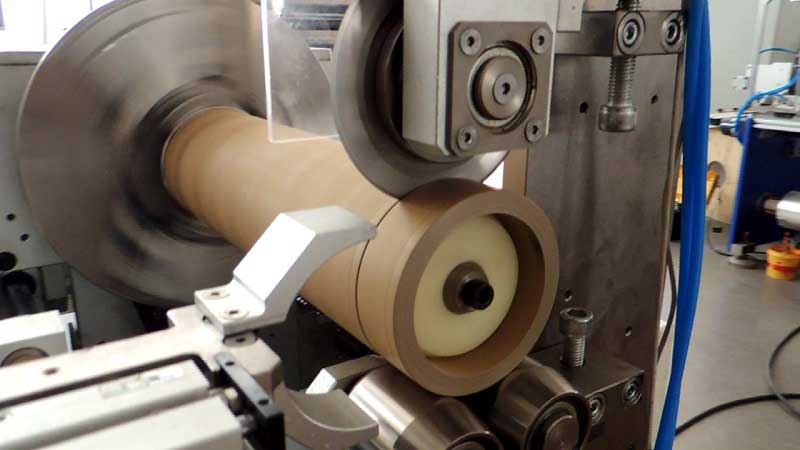

3. The knives, fixtures and processed parts used in the paper tube pipe cutting machine equipment must be firmly clamped and not loosened.

4. When the equipment of the paper tube cutting machine is running, the operator shall not leave the post to prevent no one from disposing of the problem.

5. After the work is over, the switch should be turned off, the cutter and workpiece should be withdrawn from the working position, the working site should be cleaned up, the parts, fixtures, etc. should be placed neatly, and the equipment of the paper tube pipe cutting machine should be cleaned well.

Slitting, this seemingly simple action, is actually the ultimate pursuit of precision.

03. March, 2026

They will be shipped to cigarette packaging factories, wine box factories, gift wrapping companies, and finally become those memorable and beautiful packaging in our hands.

03. March, 2026

Every micron-level improvement in slitting accuracy, every percentage decrease in scrap rate, is a scale of industry progress.

03. March, 2026

With the advancement of Industry 4.0, paper slitting machines are moving in the direction of smarter and more connected.

25. October, 2025

Before formulating a slitting plan, it is essential to fully understand the properties of each material and its impact on the slitting process.

23. September, 2025