Selection guide for slitting machines for different materials

Selection of film material slitting machine

Applicable models:

• Cantilever slitting machine (for thin films)

• Twin shaft slitting machine (suitable for thicker or laminated films)

• Round knife slitting machine (high precision required)

Key Considerations:

• Tension control system (high accuracy required)

• Static Eliminator

• Edge uniformity requirements

• Slitting speed (typically 50-800 m/min)

• Winding method (center or surface winding)

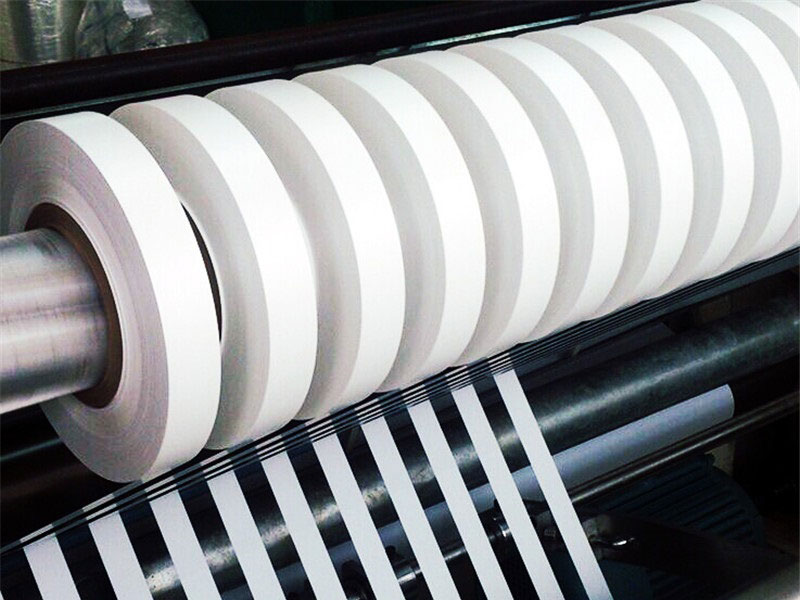

Selection of paper material slitting machine

Applicable models:

• Flat knife slitting machine (plain paper)

• Air knife slitting machine (high-grade paper products)

• Combined slitting machine (cardboard, cardboard)

Key Considerations:

• Dust collection system

• Tool wear resistance

• Slitting thickness range (from tissue to cardboard)

• Anti-wrinkle device

• Slitting speed (usually 30-300 m/min)

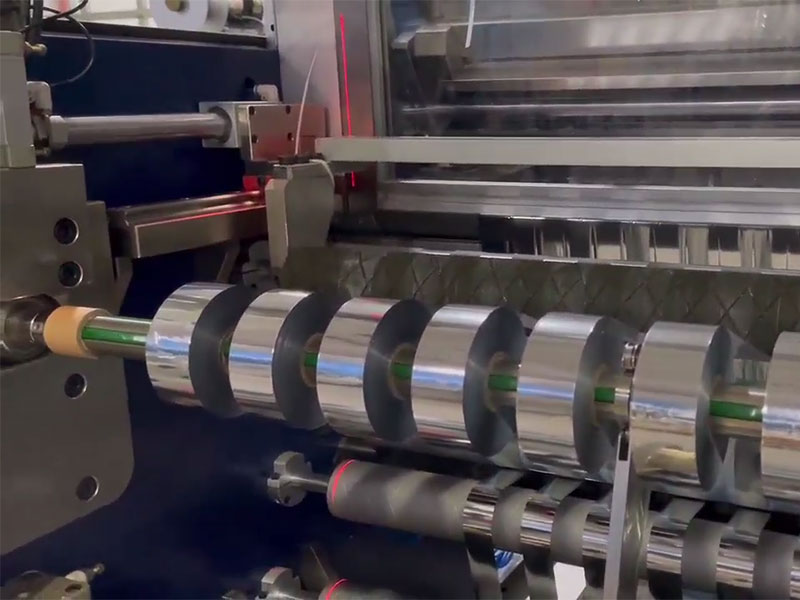

Selection of metal foil slitting machine

Applicable models:

• Heavy-duty precision slitting machine

• Hydraulic slitting machine

• High rigidity twin-shaft slitting machine

Key Considerations:

• High rigidity requirements for equipment

• Special alloy tools

• High-precision tension control (±1%)

• Edge burr control

• Slitting speed (usually 5-150 m/min)

• Lubricating oil/cooling system

General selection principle

1. Material properties: thickness, hardness, ductility, surface properties

2. Accuracy requirements: slitting width tolerance, edge quality

3. Production volume: Determine the degree and speed of equipment automation

4. Follow-up process: whether on-line inspection or special winding method is required

5. Budget: There is a large price difference from semi-automatic to fully automatic CNC equipment

It is recommended to test cut the material before the final selection to ensure that the performance of the equipment meets the actual production needs.

choosing a professional PET film slitting machine is no longer a luxury option but a necessity to remain competitive.

06. February, 2026

It slits wide film into narrow rolls of various specific widths, and its technical level directly determines the quality and production efficiency of the end product.

06. February, 2026

This article will delve into how advanced automotive film slitting machines can help businesses achieve their goal of doubling production capacity.

04. February, 2026

High tension control does not exist in isolation and needs to work in tandem with other innovative systems of the slitting machine to achieve the best results.

02. February, 2026

The bottleneck of cumbersome and slow response in the traditional slitting mode is becoming increasingly prominent.

30. January, 2026