With the continuous improvement of film slitting machine technology, the length of the bottom wrinkle is getting less and less, it is worth noting that sometimes the bottom wrinkle is not caused by the unreasonable setting of slitting parameters, but because the operator's sense of responsibility is not strong, the film is not flat on the paper tube but randomly put the film on the paper tube and then start the slitting, artificially created the wrinkle quality problem, must be paid attention to, eliminate human quality defects, improve the quality of product slitting.

Causes and countermeasures of longitudinal wrinkles

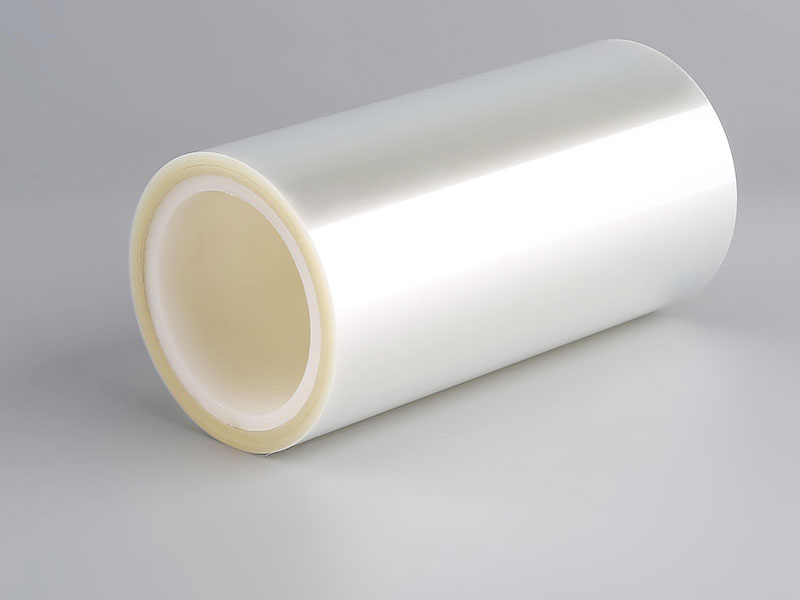

Longitudinal wrinkles are the formation of rib-like streaks on the surface of the membrane roll. In the slitting process, a large amount of air is trapped in the film roll or the accumulated uneven thickness is the main reason for the occurrence of longitudinal fringes, and it is difficult to eliminate the streaks once they appear to a more serious extent. When longitudinal wrinkles occur in the slitting process, tension reduction and pressure are generally used to exhaust the air in the film roll to improve the longitudinal wrinkle problem, but the adjustment range should consider the impact on the bottom wrinkle and other aspects. Another reason for the longitudinal wrinkle is the influence of the operation accuracy of the equipment, because the plastic film is a polymer product, and its thickness is very thin, and it is more likely to be damaged during processing, so once the operation accuracy is not enough, it is easy to produce quality problems such as longitudinal streaks. For this reason, we should be cautious when replacing equipment parts and accessories, and it is advisable to choose durable parts with high running accuracy, and a certain accuracy must be ensured during installation, otherwise it is difficult to meet the operation needs of the slitting machine. The flattening roller flattens the film and eliminates some of the longitudinal wrinkles caused by the tensile stress of the film.

Causes and countermeasures of horizontal wrinkles

In addition to the influence of the mother roll factor, the film transverse wrinkle is mainly due to the production of pit transverse wrinkles produced by the slitting film roll inside and outside tight, which is generally caused by the slitting process to reduce the pressure of the bottom wrinkle, and the slitting tension should be effectively adjusted for different types of products, and the pressure can effectively eliminate the generation of the cross wrinkle.

choosing a professional PET film slitting machine is no longer a luxury option but a necessity to remain competitive.

06. February, 2026

It slits wide film into narrow rolls of various specific widths, and its technical level directly determines the quality and production efficiency of the end product.

06. February, 2026

This article will delve into how advanced automotive film slitting machines can help businesses achieve their goal of doubling production capacity.

04. February, 2026

High tension control does not exist in isolation and needs to work in tandem with other innovative systems of the slitting machine to achieve the best results.

02. February, 2026

The bottleneck of cumbersome and slow response in the traditional slitting mode is becoming increasingly prominent.

30. January, 2026