The use of paper slitting machine environment directly affects the service life of electrical appliances. So do you know what kind of environment the paper slitter is suitable for working in?

Paper slitters work in the following environment is more suitable:

1. Good indoor ventilation.

2. Ambient temperature -10 ℃+40℃.

3. Try to avoid high temperature and humidity, humidity is less than 90%RH, no rain drips.

4. Avoid direct sunlight.

5. No flammable, corrosive gases and liquids.

6. The installation base is fixed without vibration.

7. No electromagnetic interference, away from interference sources.

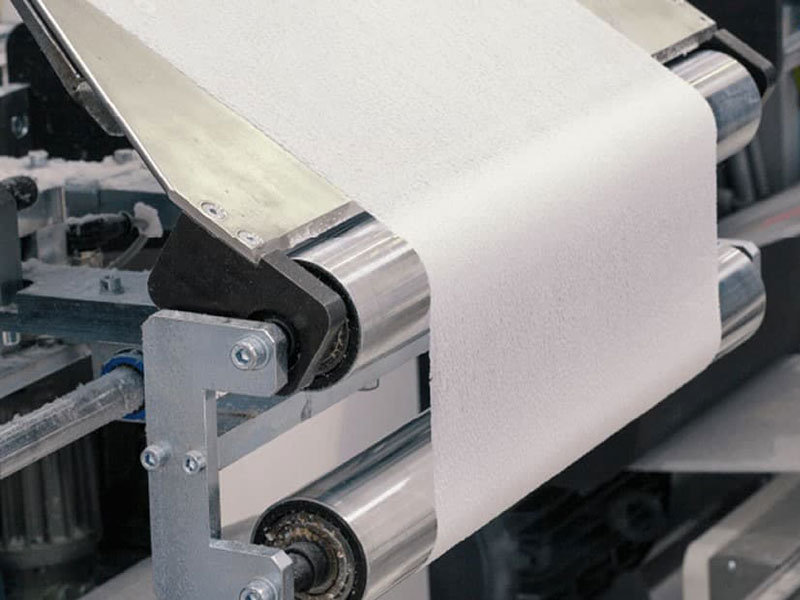

Paper slitting machine installation and use adjustment

After the paper slitting machine is unpacked, the integrity of the machine should be checked to check whether there is damage during transportation, and the correction level can be installed on a smooth and solid foundation after the inspection. After the installation and calibration level, check whether the parts are intact, whether the connecting bolts are tightened reliably, and whether the moving parts are flexible. Then fill the corresponding lubricating oil in each lubricating part. After the check and refueling is completed, the machine can be started. Start at a slow speed, and then slowly increase the cutting speed to reach normal.

With the advancement of Industry 4.0, paper slitting machines are moving in the direction of smarter and more connected.

25. October, 2025

Before formulating a slitting plan, it is essential to fully understand the properties of each material and its impact on the slitting process.

23. September, 2025

Having advanced slitting equipment and technology is itself an endorsement of the strength of the enterprise.

23. September, 2025

After slitting, the physical state of the edge of the coil of hot stamping paper directly affects the subsequent processing and application.

23. September, 2025

As a key device for post-processing, the hot stamping paper slitting machine has seen a steady growth in market demand.

20. September, 2025