The film scutcher is composed of a winding mechanism, a cutting mechanism, a winding mechanism, a functional roller and a tension control and correction control and testing device. It can make polyester film, aluminized film, BOPPLDPE, HDPE, LLDPE, PP and other films. It can also cut mica tape and PE into different sizes and is widely used in packaging and other laminating industries.

Film slitting machine blade We can roughly be divided into: square slitting blade and round slitting blade 2 kinds.

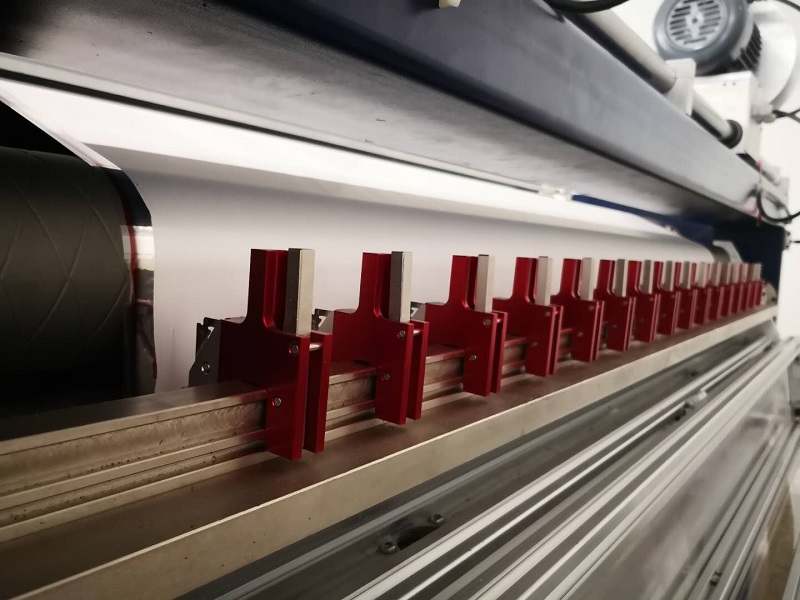

1. square cutting blade

Square scuttling blade is mainly used for scuttling all kinds of film materials. The more common square slitting blade is the three-hole blade, which is a finer tool designed to reduce the downtime of the slitting machine in operation and high-performance cutting at any time, choose from the high-performance series of pneumatic slitting knives or new non-pneumatic slitting.

2. Round slitting blade

The circular scuttling blade is mainly suitable for scuttling paper, aluminum platinum, thick sheet and other materials. Before the round blade is used, it must be subjected to a professional heat treatment.

With the help of automation technology, significantly reduce manual intervention and usher in a new phase of cost reduction and efficiency improvement.

28. February, 2026

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026

Among them, slitting effect, winding quality and tension control are the three core elements that determine the yield.

26. February, 2026

traditional slitting equipment has become difficult to meet the market's stringent needs for efficiency, precision, and flexibility.

26. February, 2026

choosing a professional PET film slitting machine is no longer a luxury option but a necessity to remain competitive.

06. February, 2026