The slitting machine can be roughly divided into three ways in the slitting process: flat knife slitting, round knife slitting, extrusion slitting. The following is a slitting machine manufacturers to introduce you to the slitting machine in the extrusion slitting.

Extrusion scuttling, this scuttling method can cut relatively thin plastic film, but also can cut relatively thick paper, non-woven fabrics, etc., is a more convenient scuttling method, so it is a development direction of non-woven scuttling machine scuttling method.

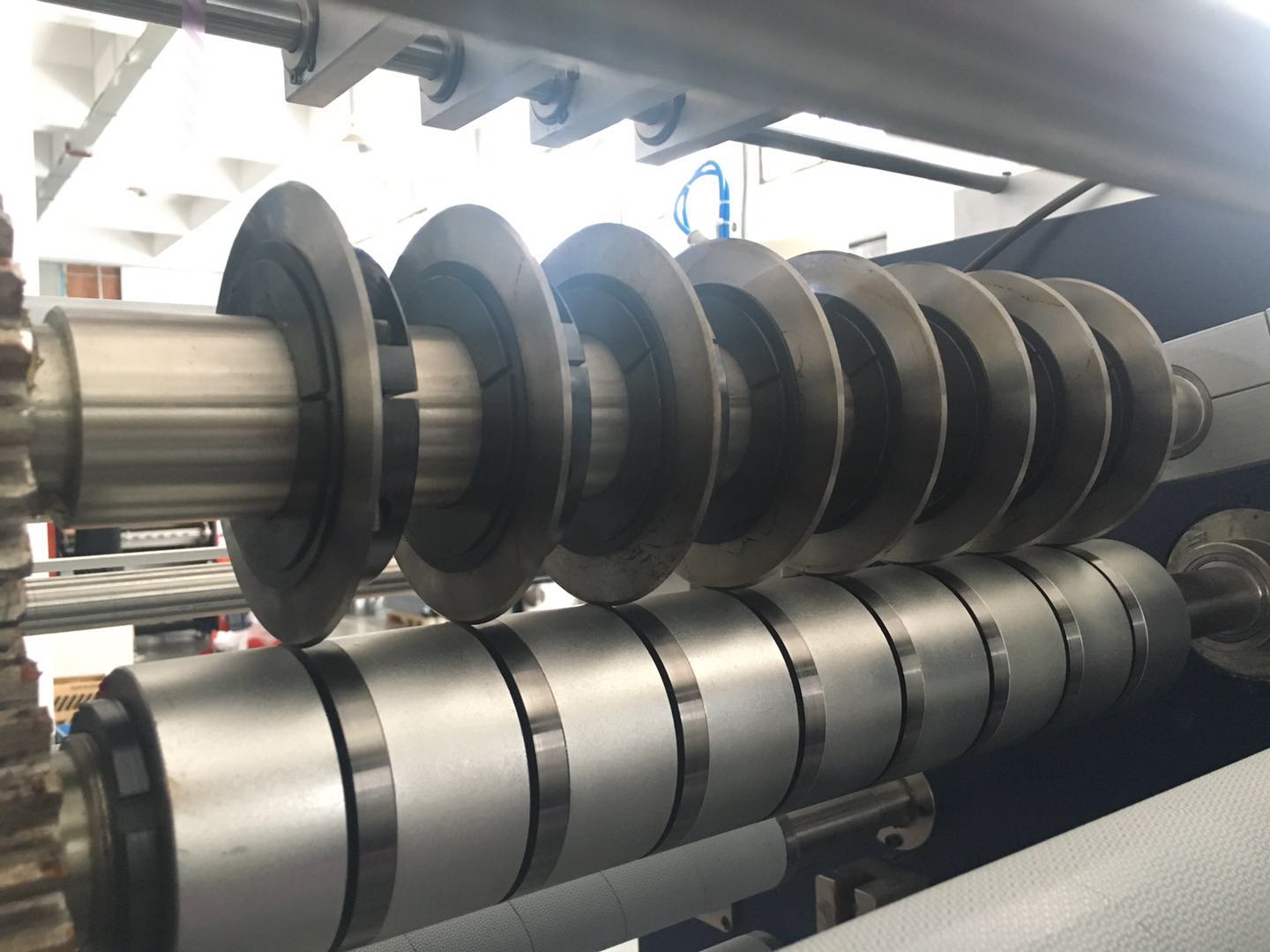

Extrusion scuttling is not common in the domestic scuttling machine, extrusion scuttling is mainly composed of a roller and a pneumatic knife which is synchronized with the speed of the material and has a certain enveloping Angle with the material.

This scuttling method can be used to cut relatively thin plastic film, but also to cut relatively thick paper, non-woven fabrics, etc., is a more convenient scuttling method, is a development direction of scuttling machine scuttling method.

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026

It is not only production equipment, but also a key lever for enterprises to leverage profit growth by reducing costs, increasing efficiency and improving quality.

28. February, 2026

With the help of automation technology, significantly reduce manual intervention and usher in a new phase of cost reduction and efficiency improvement.

28. February, 2026

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026