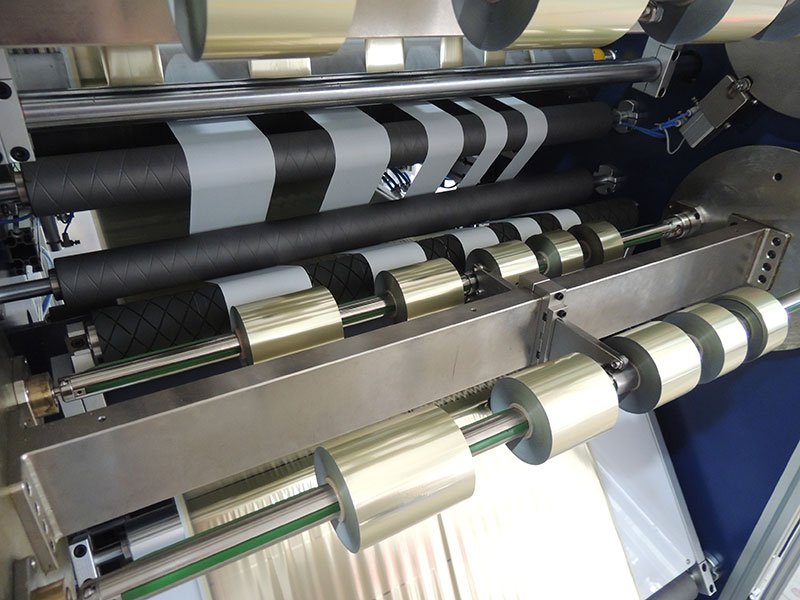

A slitting machine is a machine used to divide the roll material into multiple strips, and tension is an important parameter during the operation of the slitting machine. The correct tension setting of the slitting machine can help to achieve efficient, stable and high-quality production. The tension setting of the slitting machine is usually controlled by two ways: tension control and tension controller. The tension controller is realized by controlling the position of the roller and the rotation of the tension adjustment handle, when the material passes through the roller, the position of the roller and the rotation of the tension adjustment handle can control the tension of the material.

The tension controller is realized by controlling the tensioning device on the tension controller, and the tension control of the material can be realized by adjusting the force of the tensioning device.

To set the tension of the slitting machine correctly, the following factors need to be considered:

1. Type of material

Different types of materials need to be set with different tensions, which need to be adjusted according to factors such as the thickness, strength, surface roughness, and bending of the material.

2. Material speed

The speed of the material has a significant impact on tension control and needs to be tested and adjusted at different operating speeds.

3. Slitting machine structure

The structure of the slitting machine also affects the tension setting, such as the diameter of the roller, the way the material is conveyed, the position of the tension controller and the sensitivity of the tension adjustment handle.

When setting the tension, it should be noted that too high or too low tension will affect the production efficiency and product quality, and it needs to be adjusted according to the actual situation to achieve the best production efficiency.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026