There are some precautions when using the slitting machine, the staff should standardize the operation of the slitting machine, otherwise it is easy to have accidents.

The slitter is an important piece of equipment, so the following should be paid attention to when using it safely:

1. Start-up: Before starting, check whether all parts of the slitting machine are normal, check whether the voltage and current are stable, check whether the main hydraulic drive system has a smell and whether the pressure display is normal and stable, open the pneumatic shut-off valve, check whether the air pressure value is normal and stable, and can be used normally after checking.

2. Set the control: set the slitting menu according to the thickness type, length and width of the material to be cut. Mention the relevant file in the PDF. Set the length and style of the material after cutting. Select the appropriate rewinder, adjust the roller arm and roller, and install the paper core that suits the specification.

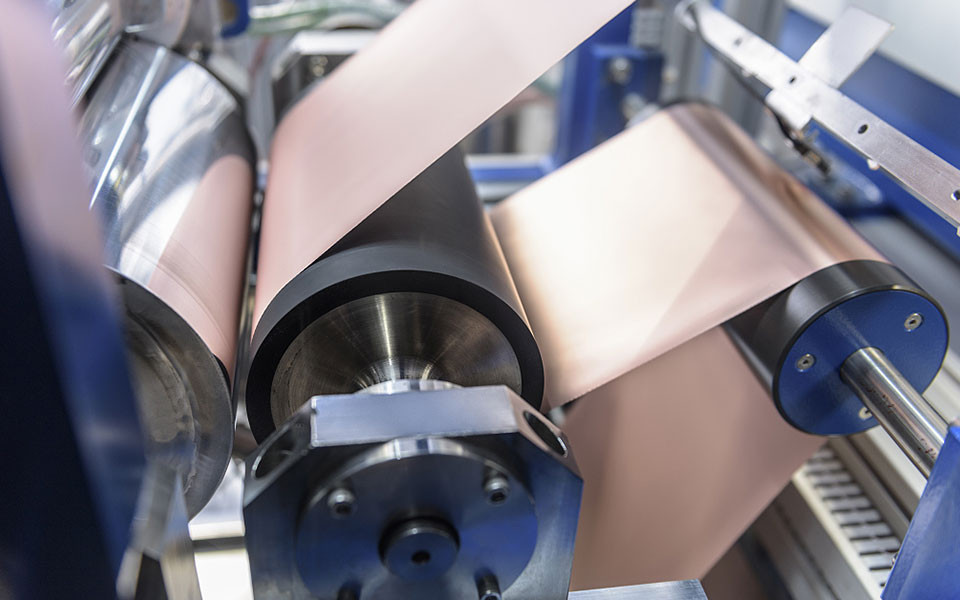

3. Feeding, film threading, film: When cutting the film material, adjust the slitting machine to put the film material into the slitting frame according to the slitting requirements, and control the button to clamp the steel core. When there is no film on the slitting machine, the film is threaded, and one end of the original film is tied to the film thread chain eye, and the film threading function can be started. When there is a film on the slitting machine and the roll joint needs to be changed, the operator needs to flatten the upper section of the first traction roller of the slitting machine, start the vacuum pump to suction the film, make the film flat and adsorb to the film receiving table, and paste the double-sided tape to style the excess film, flatten the film on the unwinding rack, use the vacuum pump to suck the film to adsorb, take off the paper layer on the tape to flatten the adhesive film, and then turn off the vacuum pump to retract the film receiving table.

4. When everything is ready, you can start running and cut the material.

5. In the slitting process, the operation effect of the slitting machine should be carefully observed, and the speed, tension, contact pressure and so on of the slitting machine can be adjusted if necessary.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026