In modern industrial production, slitting machines have become the preferred equipment for many industries with their efficient and precise cutting capabilities. So, how does the slitter improve production efficiency and quality? Let's dive in.

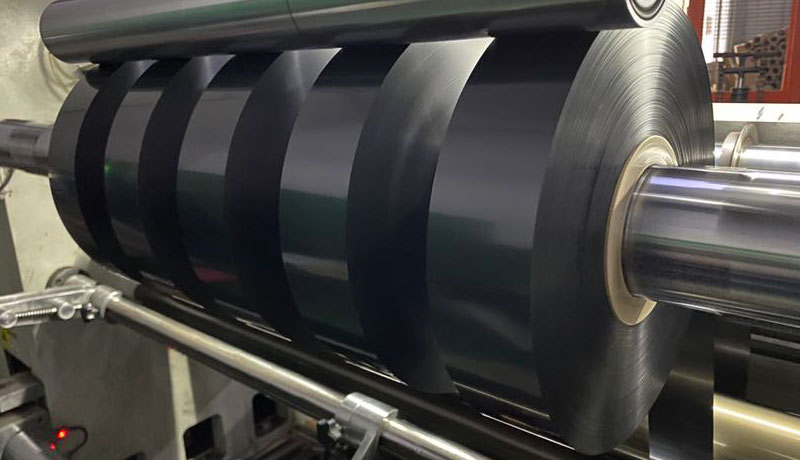

First of all, the slitting machine adopts advanced cutting technology. It is equipped with high-precision cutting knives and a precise control system that can achieve a fast and accurate cutting process. Whether it's film, paper or other flexible materials, the slitter can handle it with ease, ensuring precision and consistency every cut. Compared with traditional manual or semi-automatic cutting methods, the slitting machine can greatly improve production efficiency, reduce labor costs, and reduce the error rate.

Secondly, the slitting machine has intelligent automation functions. It can complete the entire cutting process automatically through preset programs and parameters, without manual intervention. Operators can simply set up and monitor for efficient production. The slitter can also carry out real-time data interaction and collaboration with the production line or other equipment to achieve seamless connection of the production process and further improve the overall production efficiency and quality.

In addition, the slitting machine focuses on reliability and stability. It uses high-quality materials and components, a rugged body structure and excellent immunity to interference. The slitting machine is also equipped with a complete fault detection and alarm system, which can find and eliminate possible problems in time to ensure the continuity and stability of production. This reliability and stability provides enterprises with long-term stable production guarantees, reducing downtime and maintenance time and costs.

All in all, the slitting machine improves production efficiency and quality through advanced cutting technology, intelligent automation functions, and the guarantee of reliability and stability. It plays an important role in many industries, bringing efficient and precise cutting solutions to enterprises, improving the competitiveness and efficiency of production.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026