In modern industrial production, slitting machines are widely used in various fields. So, what is unique about the slitter and why is it a key tool to maximize production efficiency? Let's explore the mysteries together.

First of all, let's think about the role and significance of the slitting machine. In the manufacturing industry, product slitting is a very important process. Traditional manual or semi-automatic slitting is often time-consuming and inefficient, prone to errors. Through automatic design and high-precision operation, the slitting machine can complete the slitting task with faster speed and higher precision. This not only improves production efficiency, but also reduces the occurrence of manual errors, thus greatly improving production efficiency.

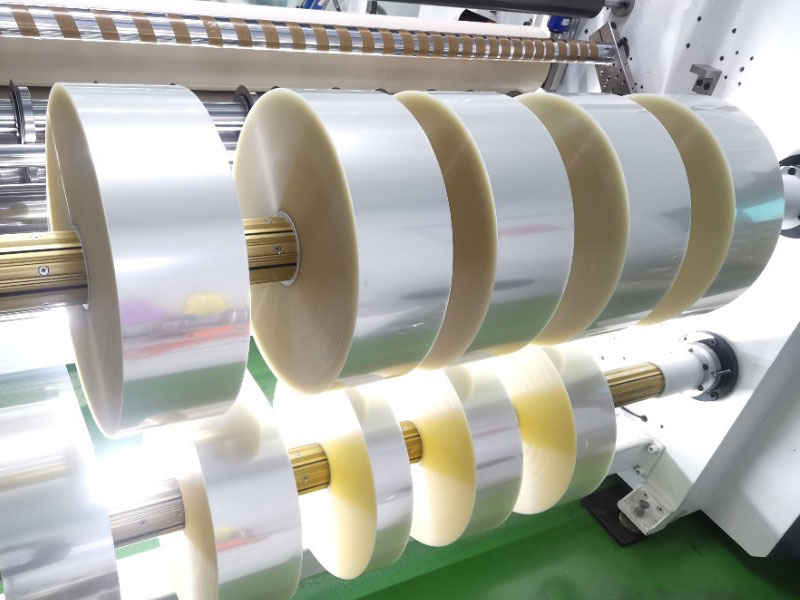

Secondly, let's explore the working principle of the slitting machine. The slitting machine adopts advanced control system and high-precision sensor, which can achieve accurate positioning and cutting of materials. Through pre-set parameters and programs, the slitter is able to automatically identify the size and characteristics of the material and perform precise cutting operations. Moreover, the slitting machine is usually also equipped with automatic stacking and arrangement functions, so that the slitted products can be automatically stacked and sorted, improving the efficiency and effectiveness of production.

In addition, the design and innovation of the slitter machine is also one of the reasons for its popularity. Modern slitting machine pays attention to ergonomic design, and the operation interface is simple and easy to understand, which is easy for operators to use and control. At the same time, the slitting machine is also equipped with safety protection devices to ensure the safety of operators and equipment. In addition, some slitters are equipped with intelligent functions, such as automatic fault detection and alarm systems, which can effectively prevent and reduce failures and downtime in production.

In short, with its efficient, precise and innovative characteristics, slitting machine has become an indispensable key tool in modern industrial production. Not only does it increase productivity and efficiency, but it also reduces human error and safety risks. With the development of science and technology and the progress of the manufacturing industry, slitting machines are expected to further develop and innovate, providing a greater degree of automation and intelligence for production, and helping enterprises achieve more efficient and sustainable production.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026