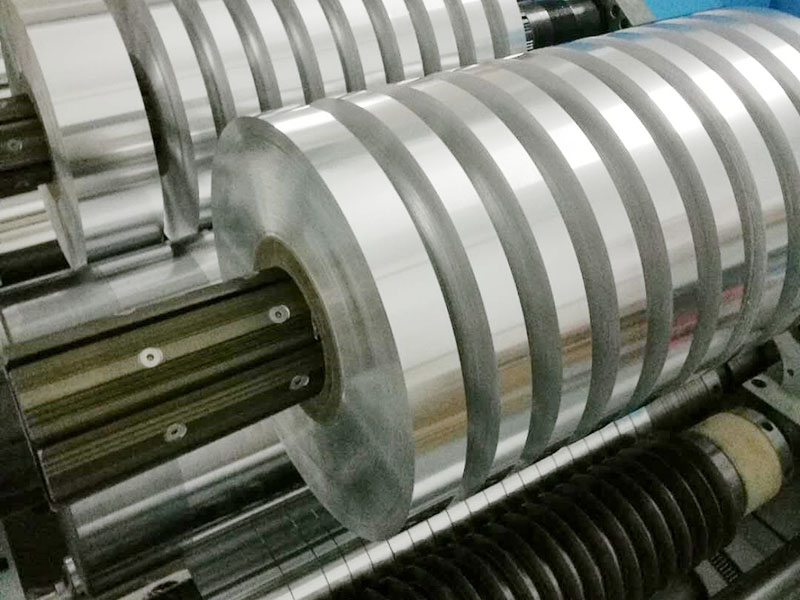

For the problem of running shaft, it is necessary to carry out a comprehensive inspection and maintenance of the slitting machine, and today we will understand what are the reasons for the running shaft of the slitting machine.

The reasons that cause the slitter to run the shaft may include the following aspects:

1. Tool wear or damage:

If the knives used in the slitter are severely worn or damaged, it will lead to inaccurate cutting, causing the paper or other materials to deviate during the cutting process, which will lead to the occurrence of the phenomenon of running shaft.

2. Uneven tension:

During the slitting process, if the tension of the paper or other material is not evenly distributed, it may cause the material to be subjected to uneven force during cutting, which may cause the shaft to run. This can be caused by a malfunction of the tension control system, a failure of the tension sensor, or an uneven tension in the material itself.

3. Material quality problems:

If the paper or other material handled by the slitter has quality problems, such as uneven thickness, surface defects, or uneven edges, it can lead to inaccurate cuts, which can lead to shaft running.

4. Improper cutterhead offset or adjustment:

If the cutterhead of the slitting machine is offset or adjusted improperly, it may cause the cutting line to be inconsistent with the movement direction of the material, resulting in the phenomenon of running the shaft.

5. Lubrication problems:

If there is a problem with the lubrication system of the slitter, such as insufficient lubricating oil or a faulty lubrication system, it may lead to increased tool friction or increased cutting resistance, which in turn can cause the running shaft.

6. Wrong operation or improper maintenance:

Improper operator operation or improper maintenance can also lead to the slitter running shaft. For example, tools that are not replaced in time, improper tension adjustment, and poor cleaning can be potential causes of the running shaft.

In view of the problem of running shafts, it is necessary to carry out a comprehensive inspection and maintenance of the slitting machine. This includes checking the wear of the tool, adjusting the tension control system, ensuring that the cutterhead is adjusted correctly, checking the lubrication system, training the operator, etc., to reduce the occurrence of the running shaft phenomenon and improve the stability and reliability of the slitter.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026