First, introduction

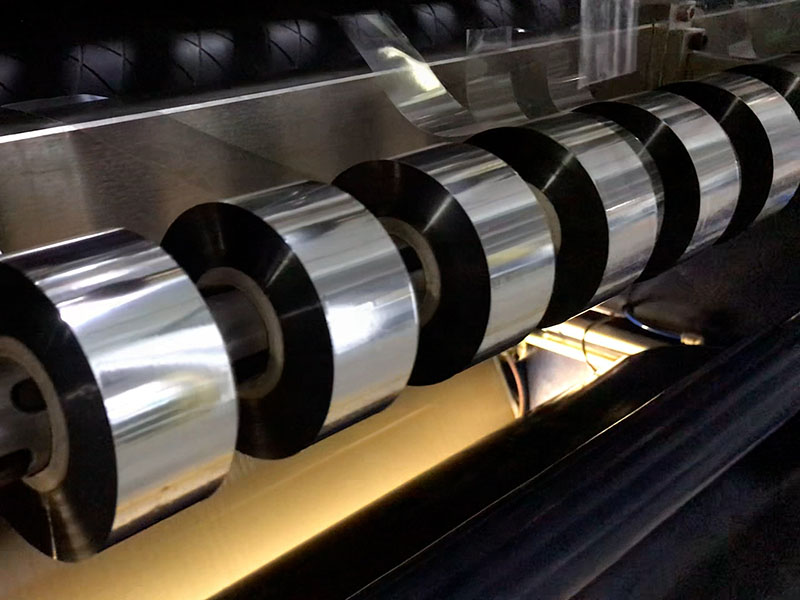

The slitting machine is widely used in processing coil products, and it can cut large coils into the required specifications. However, some problems that arise in the production process can also arise. One of them is that the slitter is not rewinding evenly, which may affect the subsequent processing and use. This article will analyze the causes of uneven winding and introduce solutions to this problem.

Second, the reason for the uneven winding

1. Uneven tension

Uneven winding is usually caused by uneven tension. This can be caused by a malfunctioning spring, a damaged tension control device, an incorrect tension setting, or a malfunctioning tension transmission system. When the tension is uneven, it is difficult to achieve uniform winding even if the surface quality of the coil is good.

2. Poor blade quality

If the blade is not sharp or uneven, it will create cracks or angular edges when splitting, which will cause the web to appear loose or uneven when winding.

3. Sliding friction

Sliding friction is another cause of uneven winding, when there is an error in the winding of the coil, under the influence of sliding friction, resistance is generated, resulting in bearing wear, and eventually leading to uneven winding.

Third, the solution of uneven winding

1. Check the tension control system

If the winding is uneven due to uneven tension, then it is necessary to consider whether the tension control system is working properly. Inspect all components involved in tension, especially the main control circuit board and electronic sensors.

2. Replace the cutting edge

In order to guarantee an even cut and sharp edges, the cutting edge should be checked and replaced frequently. Choose the right tool according to the texture of different materials.

3. Regular maintenance

Before and after using the slitter, you should check whether the friction is even. Lubricate your machine regularly to reduce wear and extend your life.

Fourth, summary

Uneven winding is a common problem in the manufacturing process and can cause other hidden dangers in the slitting process. Uneven tension, poor edge quality, sliding friction and other factors can lead to uneven winding. Solving this problem requires regular maintenance of the machine, replacement of tools, repair or renewal of the tension control system. By taking appropriate measures, we can improve the winding efficiency, reduce production costs, and lay a more solid foundation for the long-term development of the enterprise.

The leap in its core competitiveness stems from the comprehensive empowerment of intelligent control technology.

11. February, 2026

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026

a sophisticated system that combines mechanical engineering, materials science, and intelligent control.

11. February, 2026

This article will comprehensively analyze the functional system of ribbon slitting machine and reveal how it achieves precise control from raw materials to finished products.

10. February, 2026

a machine that completes the three functions of slitting, rewinding and detection at the same time, and ribbon production ushers in an era of integrated intelligence.

10. February, 2026