Hot stamping foil slitting machine has a variety of advantages, which make it widely used in the aluminum processing industry. The following is a detailed introduction to the advantages of hot stamping foil slitting machine:

1. Efficiency:

• The hot stamping foil slitting machine adopts a combination of pneumatic and electrification technology to achieve high-speed and precise cutting operations.

• Efficient slitting capacity can significantly improve production efficiency and reduce production costs.

2. Accuracy:

• The hot stamping foil slitting machine is equipped with an electrified control system, which is able to precisely control the cutting depth and speed.

• This precision ensures the stability and reliability of the cutting quality and meets the needs of high-precision machining.

3. Stability:

• The hot stamping foil slitting machine provides a stable power source during the working process, which ensures the good working condition of the equipment during long-term operation.

• Stability is also reflected in the durability and low failure rate of the equipment, reducing maintenance and downtime.

4. Flexibility:

• Hot stamping foil slitting machine can adjust the cutting parameters and blade types according to the needs of different industry fields.

• This flexibility allows the hot stamping foil slitting machine to be used in multiple industries, so that one machine can be used for multiple purposes.

5. Wide applicability:

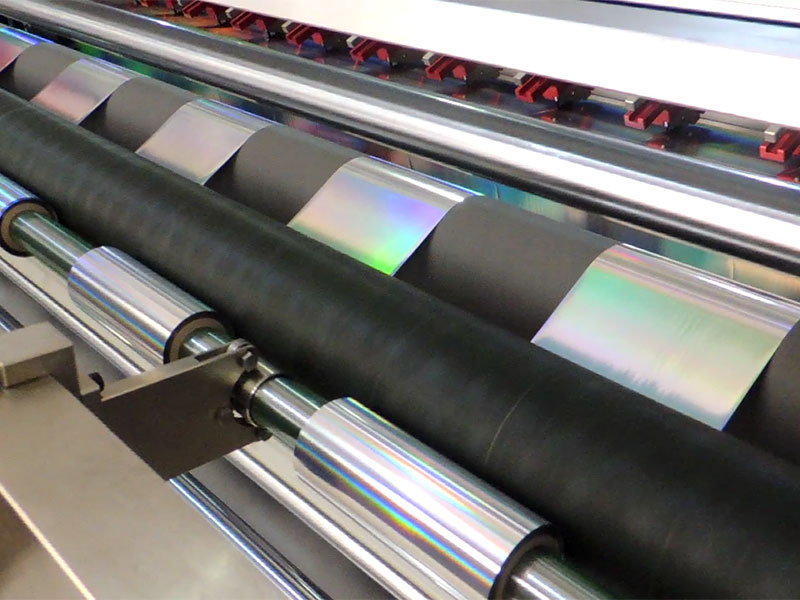

• The hot stamping foil slitting machine is not only suitable for the slitting of hot stamping foil materials, but also can be used for the slitting and rewinding of gold foil, silver foil, powder foil, composite aluminum foil, holographic hot stamping foil and other hot stamping materials.

• This wide applicability makes hot stamping foil slitting machines have application potential in multiple industries.

6. High degree of automation:

• Modern hot stamping foil slitting machines are usually equipped with advanced automation control systems, such as PLC and human-machine interface.

• These systems have the functions of automatic shutdown of metering, automatic detection of residual quantity, automatic speed adjustment of line speed, etc., which improve the degree of automation and operation convenience of the equipment.

7. Easy to operate and maintain:

• Hot stamping foil slitting machines are often designed with ease of operation and ease of maintenance in mind.

• The operation interface is clear and intuitive, so that the operator can easily get started and quickly master the operation method of the equipment.

• At the same time, the structure of the equipment is also easy to maintain and maintain, prolonging the service life of the equipment.

To sum up, the hot stamping foil slitting machine has been widely used in the aluminum processing industry and favored by users due to its advantages of high efficiency, accuracy, stability, flexibility, wide applicability, high degree of automation, and easy operation and maintenance.

this once management pain point is now transforming into a powerful tool for printing enterprises to reduce costs and increase efficiency.

26. February, 2026

This article will delve into how to make the hot foil slitting machine the engine of your production process optimization through scientific equipment selection and management.

26. February, 2026

A precision platform that integrates multifunctional applications with cross-disciplinary process expansion.

26. February, 2026

The leap in its core competitiveness stems from the comprehensive empowerment of intelligent control technology.

11. February, 2026

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026