As a professional cutting equipment, hot stamping foil slitting machine has shown a series of significant advantages and characteristics in the aluminum processing industry. The following is a detailed introduction to the advantages and characteristics of hot stamping foil slitting machine:

advantage

1. Efficient Cutting:

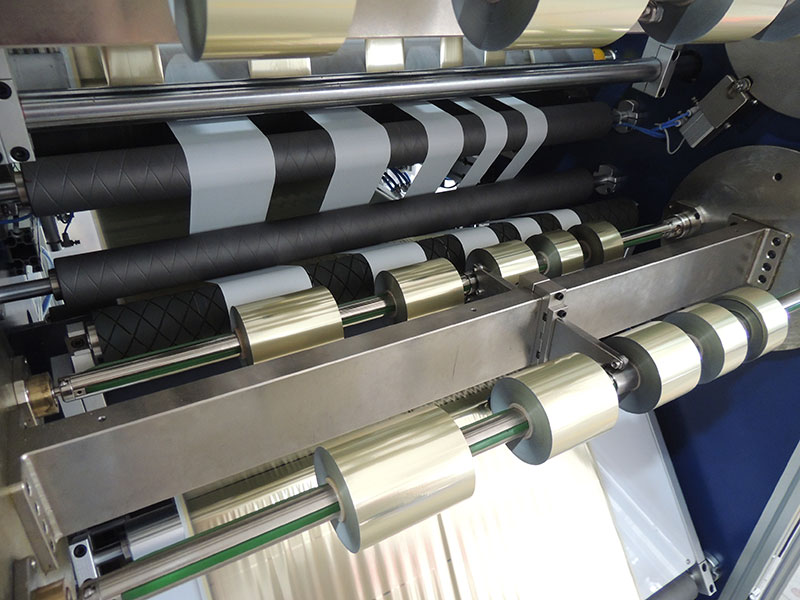

• The hot stamping foil slitting machine adopts advanced cutting technology and efficient motor drive, which can achieve fast and accurate cutting operations.

• This not only increases production efficiency, but also reduces energy consumption and costs.

2. High Accuracy:

• The hot stamping foil slitting machine is equipped with a high-precision control system and sensor, which is able to monitor and adjust the cutting parameters in real time.

• This ensures the accuracy and consistency of the cutting results, meeting the requirements of high-precision machining.

3. Good Stability:

• The hot stamping foil slitting machine is designed with the stability and durability of the equipment in mind, and adopts strong and durable materials and structures.

• This allows the equipment to maintain stable performance over long periods of operation, reducing breakdowns and downtime.

4. Strong applicability:

• Hot stamping foil slitting machine is suitable for processing a variety of aluminum materials, including materials with different thicknesses, widths and lengths.

• This enables the equipment to be widely used in multiple industries, such as printing, packaging, electronics, decoration, etc.

5. High degree of automation:

• Modern hot stamping foil slitting machines are usually equipped with advanced automation control systems and human-computer interaction interfaces.

• These systems can automatically complete the setting of cutting parameters, the monitoring of the cutting process and the output of cutting results, which improves the degree of automation and operation convenience of the equipment.

peculiarity

1. Good cutting quality:

• The hot stamping foil slitting machine adopts high-precision cutting knives and cutting processes, which can ensure the flatness and smoothness of the cutting surface.

• This gives the cut aluminum a better appearance and performance.

2. Flexibility:

• The hot stamping foil slitting machine can be flexibly adjusted according to different cutting needs, such as cutting speed, cutting depth, cutting angle, etc.

• This allows the machine to be adapted to a wide range of cutting scenarios and process requirements.

3. Easy to operate and maintain:

• The operation interface of the hot stamping foil slitting machine is usually designed to be simple and straightforward, so that the operator can easily get started and quickly grasp the operation method of the equipment.

• At the same time, the maintenance of the equipment is relatively simple and convenient, reducing maintenance costs and downtime.

4. Energy saving and environmental protection:

• The hot stamping foil slitting machine is designed with full consideration of energy saving and environmental protection requirements, and adopts a motor and control system with low energy consumption and low noise.

• This not only reduces energy consumption and environmental pollution, but also improves the sustainability and market competitiveness of the equipment.

To sum up, the hot stamping foil slitting machine has the advantages and characteristics of efficient cutting, high precision, good stability, strong applicability, high degree of automation, good cutting quality, strong flexibility, easy operation and maintenance, energy saving and environmental protection. These advantages and characteristics make the hot stamping foil slitting machine widely used and recognized in the aluminum processing industry.

this once management pain point is now transforming into a powerful tool for printing enterprises to reduce costs and increase efficiency.

26. February, 2026

This article will delve into how to make the hot foil slitting machine the engine of your production process optimization through scientific equipment selection and management.

26. February, 2026

A precision platform that integrates multifunctional applications with cross-disciplinary process expansion.

26. February, 2026

The leap in its core competitiveness stems from the comprehensive empowerment of intelligent control technology.

11. February, 2026

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026