In the manufacture of film capacitors, the capacitor film slitting machine is one of the key equipment, and its industry adaptability directly affects the performance, production efficiency and cost of film capacitors. Here are the key analyses of the suitability of the equipment industry:

1. Core suitability requirements

• Material compatibility

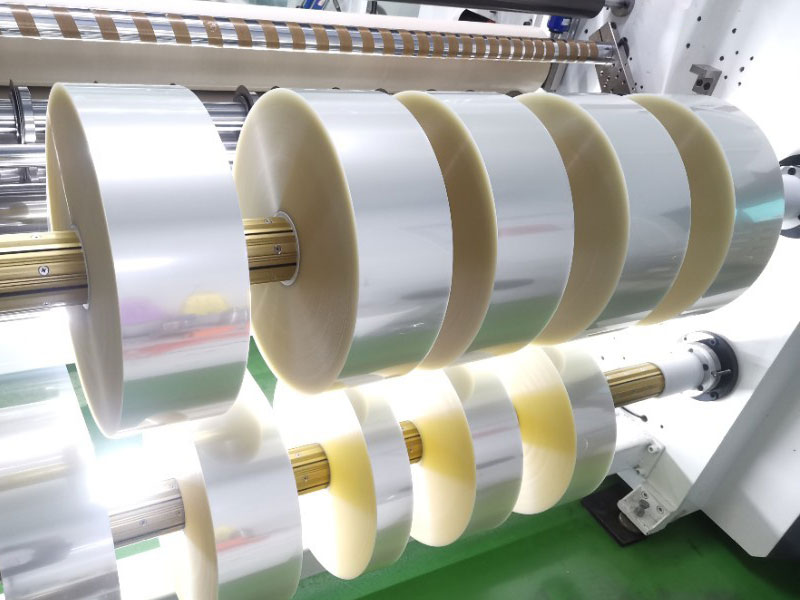

It is necessary to adapt to different film materials (such as PP, PET, PPS, etc.), and avoid edge burrs, tensile deformation or thermal damage during slitting to ensure stable dielectric properties.

• Thickness and width accuracy

The thickness of the film is usually 2-10μm, and the slitting width error needs to be controlled within ±0.1mm to meet the stacking consistency of high-frequency and high-voltage capacitors.

• Tension control

High-sensitivity tension systems (e.g. magnetic particle braking or servo control) prevent film wrinkles or breakage, especially for ultra-thin films (e.g. below 3 μm).

2. Industry-specific requirements

• New energy field (electric vehicles, photovoltaics)

◦ Requirements: High withstand voltage, large capacitance, slitting machine needs to process wide film (such as more than 1m) and maintain uniformity.

◦ Adaptation scheme: Equipped with online defect detection (such as CCD vision) and automatic deviation correction system to ensure that there is no defect after slitting.

• Consumer Electronics (Miniaturized Capacitors)

◦ Requirements: narrow slitting (such as less than 5mm) and high speed (>500m/min), the equipment needs high rigidity tools and dynamic balance system.

• Industrial power (high frequency, high voltage capacitors)

◦ Requirements: The slitting edge finish is required to be high, and laser or nanoblade technology is required to reduce microscopic cracks.

• Intelligent

Integrated IoT sensors monitor slitting parameters (tension, temperature, vibration) in real time, and optimize process parameters through AI algorithms to reduce scrap rates.

• Green manufacturing

Low energy consumption design (such as variable frequency drive) and oil-free lubrication system to meet the requirements of environmental regulations.

• Modular design

Quick-change tool/winding module for high-mix, low-volume production (e.g. in the field of flexible electronics).

4. Challenges and solutions

• Challenge: Inconsistent shrinkage after slitting due to differences in film ductility.

Solution: pre-stretch process compensation or temperature-controlled slitting environment.

• Challenge: The conductive layer at the edge is peeled off during slitting of metallized films (e.g. aluminized).

Solution: low-temperature laser slitting or ultrasonic tools.

5. Market Trends

• Acceleration of domestic substitution: domestic equipment manufacturers have gradually broken through the ultra-thin slitting technology, and the cost performance is better than that of imported equipment.

• Growing demand for customization: For emerging fields such as 5G and automotive capacitors, slitting machines need to be linked with coating and winding equipment to form an integrated production line.

summary

The adaptability of the capacitor film slitting machine needs to be continuously optimized around the material characteristics, terminal application scenarios and intelligent trends. In the future, the competition will focus on precision stability, customized services and synergy with upstream and downstream processes. Manufacturers work with film suppliers and capacitor manufacturers to develop dedicated solutions.

The tool holder driven by servo motor can achieve a positioning accuracy of ±0.01mm, reducing the burr on the edge of the film.

21. June, 2025

It has evolved from a single processing equipment to an intelligent production unit integrating perception, decision-making and execution.

20. June, 2025

The following is a professional analysis from three aspects: technical characteristics, application scenarios and industry trends:

19. June, 2025

high-precision slitting (accuracy ± 1μm) and tension control (±0.5N) ensure that the film is not damaged.

18. June, 2025

The key to improving the productivity of capacitor film slitting machines is to optimize the tool change process and realize automatic adjustments

17. June, 2025