The key to improving the productivity of capacitor film slitting machines is to optimize the tool change process and realize automatic adjustments, and the following are the specific solutions:

First, optimization of quick tool change system

1. Modular turret design

◦ Using pre-set tool holder, the tool is pre-sized offline (such as using tool setter), and the tool is directly inserted and locked when changing the tool, which shortens the online adjustment time.

◦ Equipped with hydraulic or pneumatic quick clamping device to achieve second tool change (e.g. from the traditional 10 minutes to 30 seconds).

2. Intelligent tool management system

◦ Integrate RFID tags or QR codes to automatically identify tool parameters (such as cutting edge angle, wear status) to avoid manual input errors.

◦ Predictive maintenance: Monitor tool wear with vibration sensors and trigger tool change reminders in advance to reduce sudden downtime.

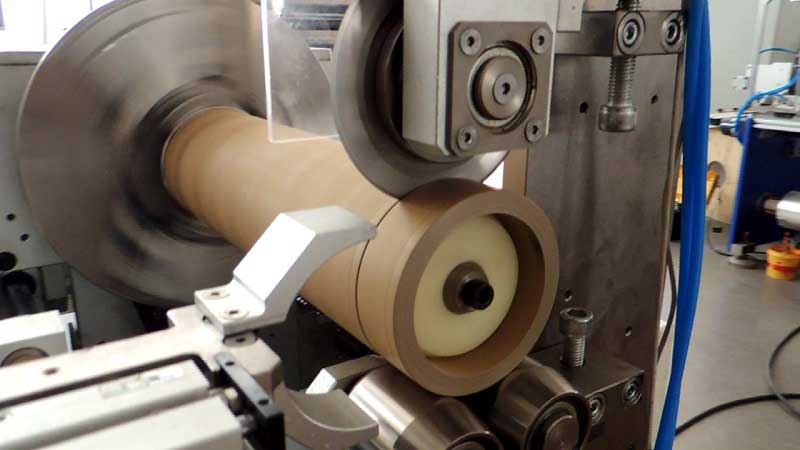

3. Manipulator-assisted tool change

◦ The cobot automatically disassembles the old knife and installs the new one, especially for heavy-duty knife rollers or high-risk scenarios.

Second, automatic adjustment technology

1. Closed-loop tension control

◦ High-precision tension sensor + servo motor is used to dynamically adjust the unwinding/rewinding tension (such as within ±0.5N) in real time to reduce the wrinkling or fracture of the film.

2. Vision-guided correction system

◦ The industrial camera detects the edge position of the film and controls the guiding roller through the PID algorithm to achieve ± 0.1mm accuracy (±1mm for traditional mechanical guidance) and reduce waste.

3. Adaptive slitting parameters

◦ Based on the film material (e.g., PP, PET) and thickness, it automatically matches the optimal knife pressure, speed and other parameters (e.g., the process recipe is stored by PLC).

Third, auxiliary measures for efficiency enhancement

1. Parallel slitting design

◦ Multi-station slitting heads work in parallel, only a single station is stopped when changing tools, and the rest continues to produce (efficiency increased by 30%+).

2. Digital twin simulation

◦ Rehearse tool changes and adjustment processes in a virtual environment to optimize the action path and reduce the actual commissioning time.

3. Energy consumption optimization

◦ Automatically switch to low-power mode during tool change to reduce standby energy consumption (e.g., the standby power of conventional equipment is optimized from 15kW to 5kW).

Fourth, reference for implementation cases

• An equipment manufacturer: Through pneumatic quick-change tool holder + AI tension control, the tool change time is compressed from 8 minutes to 45 seconds, the slitting speed is increased to 600m/min (the industry average is 400m/min), and the scrap rate is reduced to less than 0.3%.

summary

At the heart of fast tool changes and automatic adjustments is the reduction of manual intervention time and the dynamic compensation of process fluctuations. It is advisable to prioritize the upgrade of the tension/guiding control system, and then gradually introduce modular tools and automated tool changes, with a payback period of 12-18 months.

a new generation of hot stamping foil slitting machines with convenient design is completely changing this situation.

24. December, 2025

It is recommended to start with simple cutting tasks and gradually familiarize yourself with the functions when using it for the first time.

02. August, 2025

The following is a guide to the whole process of rapid production of the ribbon slitting machine from installation to commissioning, which is clearly presented step by step to help you efficiently com

10. July, 2025

These improvements can reduce roll change downtime by 50-70% and significantly improve overall equipment effectiveness (OEE).

23. June, 2025

Reducing slitter downtime requires both preventative maintenance and quick repairs, and here are the systematic solutions:

23. June, 2025