The high-speed, dust-free cutting revolution of slitting machines in the packaging industry is mainly realized through technological innovation and system optimization. Here are the key solutions and technology paths:

1. The core technology of high-speed cutting

• High-precision servo drive system

Driven by multi-axis synchronous servo motor and linear motor, with dynamic response algorithms (such as adaptive PID control), the tool holder can be quickly positioned (speed up to 300-500m/min) and reduce mechanical delay.

• Flying Cut

Synchronous cutting in the continuous movement of the material, real-time tracking of the material speed through photoelectric sensors or encoders to ensure that the cut is smooth and free of burrs, suitable for flexible materials such as film and paper.

• Intelligent tension control

Equipped with a closed-loop tension sensor and magnetic particle brake, it can dynamically adjust the unwinding/winding tension (accuracy ± 0.1N) to avoid material tensile deformation or wrinkles and ensure stability at high speeds.

2. Dust-free cutting solution

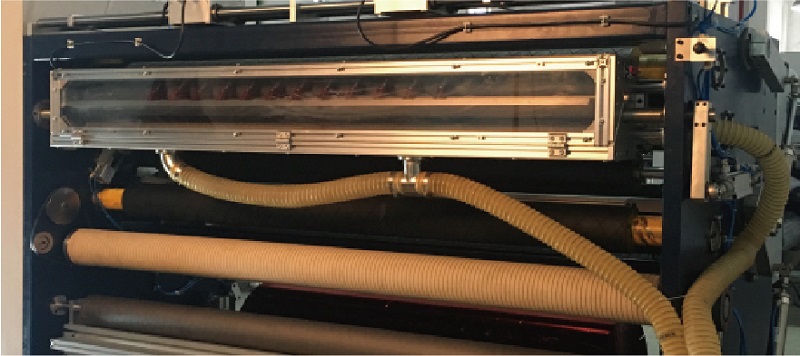

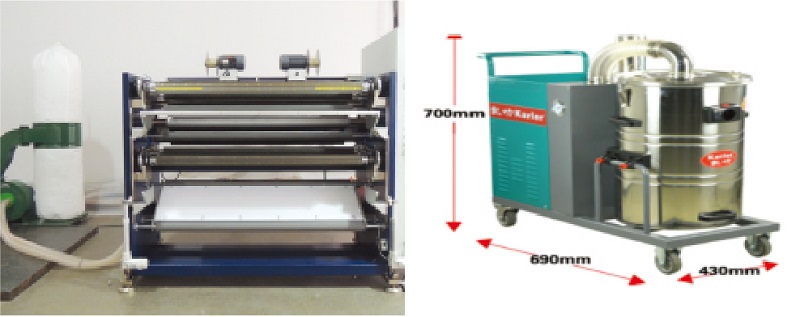

• Negative pressure adsorption dust removal system

A vacuum suction device (air volume ≥ 1000m³/h) is integrated in the cutting area, and a static eliminator is used to directly extract the particles (such as PET film dust) generated by cutting, and the dust removal efficiency is more than 99%.

• Laser cutting instead of mechanical knives

Fiber lasers (wavelength 1064nm) are used for high value-added materials such as medical packaging, and non-contact cutting reduces dust, while edge melting prevents fiber shedding.

• Tool optimization and cooling

Use diamond-coated round knives or ceramic blades to reduce friction dust; Jet cooling system reduces hot melt knife sticking.

3. Intelligent and automated upgrades

• Machine vision positioning

Real-time detection of material edges or printed marks (accuracy ± 0.05mm) through CCD cameras, automatic deviation correction (e.g. EPC systems), reducing downtime caused by manual intervention.

• Digital Twin & Predictive Maintenance

Based on the IoT sensor to collect vibration and temperature data, the AI model predicts the tool wear cycle and replaces the tool in advance to avoid tool breakage pollution.

• Modular design

Quick-change turrets and dust filters reduce cleaning and maintenance time (<5 minutes) and increase overall equipment effectiveness (OEE≥85%).

4. Industry application cases

• Flexible packaging field: aluminum-plastic composite film slitting adopts ultrasonic cutting, no thermal impact and zero dust, and the speed is up to 800m/min.

• Corrugated cardboard: high-pressure waterjet slitting system (pressure 400MPa) to achieve chipless cutting, waste water circulation filtration.

• Lithium battery diaphragm: clean room grade slitting machine, equipped with HEPA filtration (Class 100) and constant temperature and humidity control.

5. Future Trends

• Ultrafast laser technology (picosecond/femtosecond pulses) further reduces thermal damage.

• Self-cleaning coated tools (e.g. graphene-like materials) reduce adhesion dust.

• Digital printing + slitting line to achieve one-stop production of personalized packaging.

Through the integration of the above technologies, the modern slitting machine has broken through the traditional bottleneck and become the core equipment for efficient and environmentally friendly production in the packaging industry. When selecting a model, enterprises need to match the cutting method according to the material characteristics (such as thickness and ductility), and pay attention to the optimization of the energy consumption ratio of the dust removal system.

The leap in its core competitiveness stems from the comprehensive empowerment of intelligent control technology.

11. February, 2026

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026

a sophisticated system that combines mechanical engineering, materials science, and intelligent control.

11. February, 2026

This article will comprehensively analyze the functional system of ribbon slitting machine and reveal how it achieves precise control from raw materials to finished products.

10. February, 2026

a machine that completes the three functions of slitting, rewinding and detection at the same time, and ribbon production ushers in an era of integrated intelligence.

10. February, 2026