First, first of all, we must look at the degree of automation of the rewinder, the higher the degree of automation, the more intelligent the better.

Second, see whether the rewinder has the function of automatic pulling bar, automatic trimming, glue spraying, sealing synchronization at one time, which can greatly save manpower, and can improve work efficiency, only work efficiency can save our investment and bring us more benefits.

Third, see whether the rewinder can realize the automatic conversion of cores and cores, and realize the dual use of the material rewinder.

The stable operation of the slitting rewinder is the basis for producing high-quality coil products.

10. December, 2025

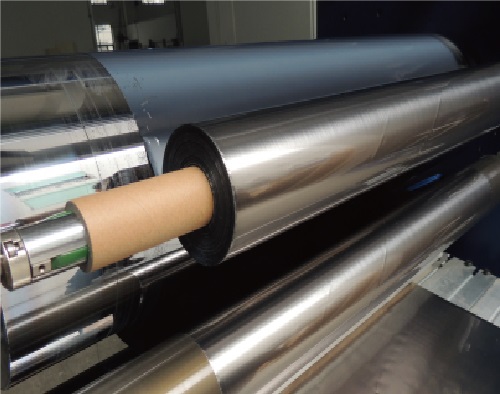

Precisely cut the wide master roll according to the preset dimensions, then rewind it into finished rolls suitable for subsequent processing or direct use.

09. December, 2025

Cut wide rolls of film, paper, nonwoven fabric, metal foil, and other materials to precise sizes, and then rewind them into finished rolls that meet downstream requirements.

09. December, 2025

A slitting rewinder is a device that slices wide coils into multiple narrow strips of material and rewinds them into independent rolls.

09. December, 2025

A suitable slitting and rewinding machine can not only greatly improve production efficiency, but also reduce material loss and ensure product quality.

08. December, 2025