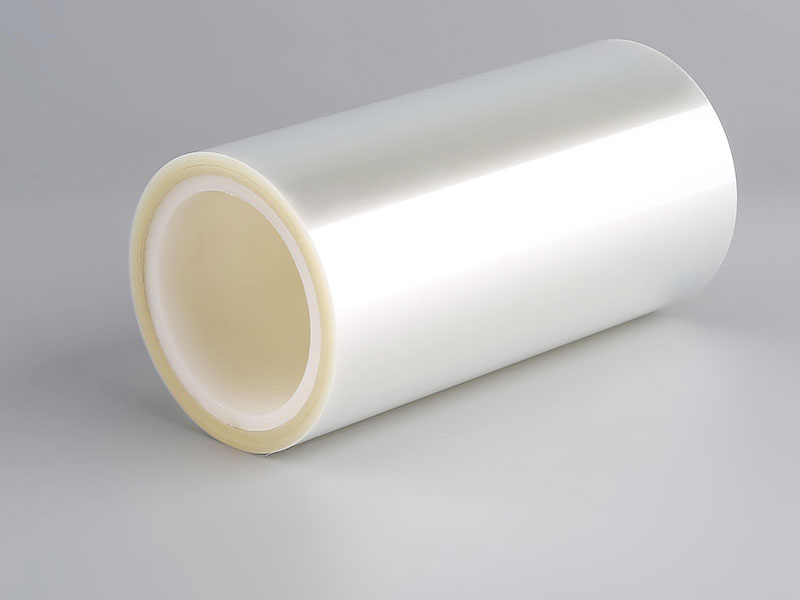

PE stretch film, also known as stretch film, is a kind of plastic film with self-adhesive and stretchable properties produced by single-sided saliva or double-sided blow molding process, which can use the viscosity and rebound characteristics between the film layers to compact the goods into a whole, and has the effect of dustproof and moisture-proof. Stretch film slitting machine is a set of slitting, rewinding and other multi-functional in one of the special slitting equipment, mainly used for large width of the stretch film/stretch film, cut into narrow film rolls, at the same time can correct the staggering of the coil, improve the flatness and appearance quality of the material.

The main type of stretch film slitting and rewinding machine

1) Semi-automatic rewinding and slitting machine. At the same time, it has the function of slitting and rewinding, and is characterized by simple structure, easy operation and convenient troubleshooting. The control system generally adopts PLC plus man-machine interface, and is equipped with main motor, flip motor and inverter control system. The unwinding end uses a magnetic particle brake to control the torque for tension control, which requires flexible adjustment of running time, speed and accurate metering. It is necessary to manually change the paper core, cut and unload. In addition, the winding station can be increased as needed to improve the winding efficiency, and the speed ratio can also be changed by changing different gears, and the stretching film can be stretched into various widths and thicknesses to achieve the pre-stretching function.

2) Fully automatic stretch film rewinding machine. It mainly rewinds the mother roll with a large roll diameter into a number of finished films with a smaller roll diameter. It is characterized by a high degree of automation, faster speed and higher efficiency. With automatic paper tube loading, automatic unloading, automatic shaft changing, automatic cutting, etc., with the conveyor belt, the machine operation and the finished product stretch film packing can be completed synchronously. The labor requirement is greatly reduced, and a single person can be competent to operate multiple machines. In addition, humanized protection functions such as automatic shutdown of film breakage and paperless shutdown of chucks can effectively eliminate potential safety hazards, save energy consumption and ensure the safe and reliable operation of the equipment.

The working principle of the stretch film rewinding and slitting machine

Compared with the conventional slitting machine, the operation process of the PE stretch film slitting machine is relatively simple, mainly including three stages: unwinding, slitting and rewinding. First of all, the unwinding inflatable shaft unfolds the winding film of the mother roll smoothly through transmission, and maintains stable operation through the tension control system to avoid the problem of dislocation and tensile deformation caused by the instability of tension. The slitting system generally adopts the method of straight knife slitting, the cutter is fixed on the cutter shaft and the spacing is set according to the slitting specifications, and the high-speed stretch film is accurately cut into a narrow material and enters the winding process. The winding mechanism generally adopts the form of jacket to facilitate the upper and lower film rolls, two paper tubes are fixed on the winding chuck, and a pressure roller is close to the material on the paper tube at the same time for surface curling, this winding method can effectively remove the air between the film layers, reduce the generation of bubbles and wrinkles, and the slitting operation is completed so far. In addition, in the rewinding mode, the two stations adopt alternate winding, and the cycle operation is carried out by turning the motor, which improves production efficiency. The design of the whole machine requires solid materials for wall panels and stable operation. The rewinding and unwinding speed is synchronized to prevent the material from being overstretched or loosened.

Application field of stretch film slitting and rewinding machine

The stretch film slitting and rewinding machine can carry out high-efficiency customized rewinding and cutting processing of stretch film, aluminized film, cling film, paper and other materials, whether it is used for the fixation of goods parcels, or product protection and isolation, or even the production of environmentally friendly biodegradable stretch film, it is inseparable from the precise operation of stretch film slitting equipment. It has gradually become an indispensable key equipment in many industries such as food, logistics, electronic production, building materials, and chemicals. With the continuous development of scientific and technological progress and market demand, the future stretch film slitting machine will develop in the direction of higher precision, more intelligent, more energy-saving and environmental protection, and continue to promote the technological innovation and industrial upgrading of the packaging industry.

1. Rough edge of the film slitterMost of the raw edge is caused by the cutting knife is too blunt, replacing the cutting knife can solve the problem. Different

06. March, 2024

The uneven end face of the film slitting machine refers to the uneven end face phenomenon that occurs when the film width remains the same.There are generally t

21. February, 2024

With the continuous improvement of film slitting machine technology, the length of the bottom wrinkle is getting less and less, it is worth noting that sometime

20. February, 2024

The effect of wrinkles on the quality of useBOPP film is commonly known as "cellophane", reflecting that the film has the characteristics of high stiffness and

19. February, 2024

In the final analysis, the blade of the film slitting machine is a kind of slitting machine blade, which can be roughly divided into: square slitting blade and

10. January, 2024