As we all know, we often have a lot of industrial dust on the machine after operating the slitting equipment, which are "toxic and harmful gases", which are prone to occupational diseases for a long time, and are very bad for the lungs.

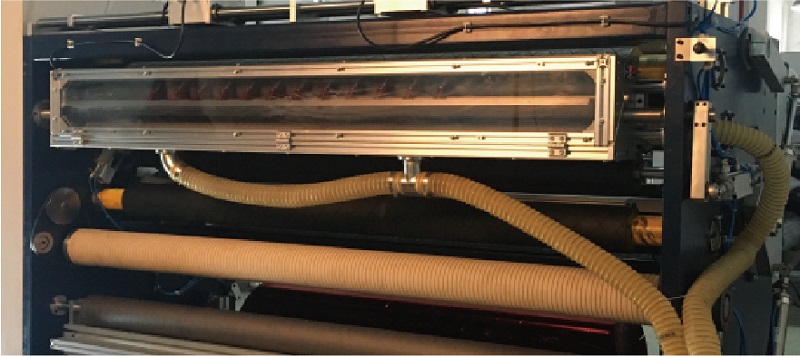

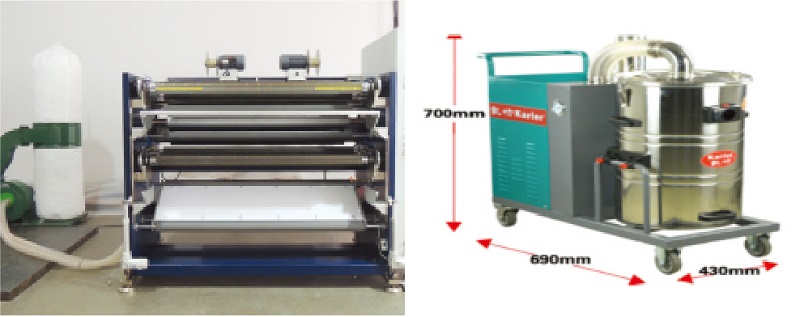

In response to this problem, the slitting machine manufacturer has researched and produced a dust treatment device, which effectively solves the problem of sucking and removing the dust generated after slitting.

Operation method: wipe by felt (white mineral oil can be added) and vacuum the dust cover; Material: tungsten carbide blade, surface treatment: grinding, polishing, full polishing; And the angle can be customized, and the bed knife can be customized according to different specifications according to customer requirements.

The scope of application is commonly found in soft materials such as paper, packaging films, and non-woven fabrics.

If you are still worried about the dust removal of the slitting machine, you may wish to consult us in detail through the Internet or telephone, or you can come to our factory to meet and negotiate.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026