In view of the low slitting efficiency of ribbons (thermal transfer ribbons, barcode ribbons, etc.), the automatic high-speed slitting machine can increase the production capacity by more than 50% through the following technical solutions, while ensuring the slitting accuracy and material integrity:

First, pain points and challenges of ribbon slitting

1. Material Properties:

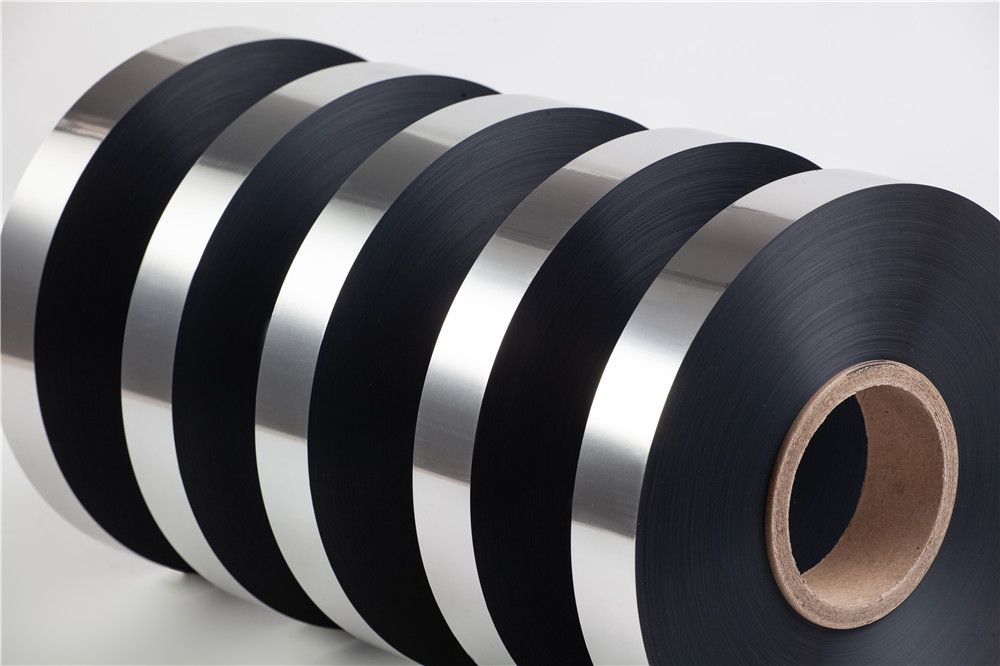

◦ Multi-layer structure (PET substrate + coating + ink), easy to delaminate or warped edges.

◦ Sensitive to tension, too much will be pulled off, too small will cause uneven winding.

2. Traditional Questions:

◦ Long downtime for manual roll change and limited slitting speed (typically ≤ 100m/min).

◦ Edge burrs and slitting dust contaminate the ink layer.

Second, the core solution of automatic high-speed slitting machine

1. Ultra-high-speed slitting module

◦ Laser Slitting/Air Knife Technology:

◦ Non-contact cutting to avoid damage to the ribbon coating caused by mechanical friction (especially suitable for wax-based/mixed-based ribbons).

◦ The cutting speed can reach 300~500m/min, which is 3 times faster than the traditional blade slitting.

◦ Dynamic Dust Collection System:

◦ Negative pressure adsorption + ionic air cleaning, slitting and removing debris at the same time to prevent contamination of the coil.

2. Fully automatic roll change and splicing

◦ Double-station winding + pre-loaded paper core:

◦ The servo-driven inflatable shaft automatically switches, and the roll change time is reduced from 3 minutes to 0 seconds.

◦ Equipped with a static eliminator to avoid film adhesion.

◦ Intelligent splicing technology:

◦ The ultrasonic sensor detects the diameter of the coil and triggers the splicing preparation in advance, and the success rate of splicing ≥ 99.9%.

3. Ribbon tension control

◦ Three-stage closed-loop tension:

◦ Unwinding (magnetic particle brake) + slitting (floating roller feedback) + winding (servo motor), tension fluctuation ≤± 0.5N.

◦ Preset tension curves for different ribbon types (resin-based/wax-based) and automatically adjust.

4. High Precision Web Guiding (EPC)

◦ Infrared + CCD dual sensor:

◦ Infrared detection of the edge of PET substrate, CCD identification of ink coating pattern, deviation correction accuracy ± 0.1mm.

◦ Anti-shake algorithm, suitable for high-speed operation of ribbon thin materials.

Third, comparative data for efficiency improvement

| index | Conventional ribbon slitting machine | Fully automatic high-speed slitting machine | Lift |

| Slitting speed | 80~120m/min | 250~400m/min | +150% |

| Roll change efficiency | 3 min/roll | 0 sec (fully automatic) | 100% |

| Yield | 85%~90% | ≥98% | +10%~13% |

| Capacity per day (8 hours) | 400~500 km | 900~1200 km | +50%~80% |

Fourth, the special optimization of ribbon slitting

1. Environmental Control:

◦ Constant temperature and humidity module (20~25°C, RH40%~60%) to prevent carbon ribbon moisture absorption or static electricity accumulation.

2. Edge Enhancement:

◦ Infrared heated edge after slitting (optional) to reduce the risk of coating peeling.

3. Dust-free guide rollers:

◦ Carbon fiber or silicone coated guide rollers to avoid scratching the ink layer.

5. Expansion of intelligent functions

• AI Defect Detection:

◦ Scan the ribbon coating uniformity online and automatically mark pinholes, bubbles and other defects.

• MES system docking:

◦ Slitting data (length, width, batch) is automatically uploaded to the factory management system to trace the whole production process.

• One-click changeover:

◦ Memorize the parameters of different ribbon specifications (e.g. 4.5mm/6mm/8mm), and the switching time is < 1 minute.

6. Applicable Scenarios

• Barcode ribbons: TTR, TTK and other thermal transfer ribbon slitting.

• Special ribbons: high-temperature resin-based ribbons, washed standard ribbons.

• Other sensitive films: release films, conductive films.

Through a fully automated design, high-speed slitting technology and ribbon-specific adaptation solutions, the machine can significantly increase production capacity and reduce losses. If you need to further customize the solution (e.g. ultra-narrow slitting or anti-oxidation needs), specific parameters are available!

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026

It is not only production equipment, but also a key lever for enterprises to leverage profit growth by reducing costs, increasing efficiency and improving quality.

28. February, 2026

This is not only an iteration of equipment, but also a comprehensive redefinition of production efficiency, material utilization and intelligent management standards.

27. February, 2026

It is in this context that the new generation of ribbon slitting machines is redefining the production standards of the industry with "precision manufacturing" as the core.

27. February, 2026