As the core processing equipment in modern industry, the slitting machine shows strong versatility in the precision cutting of film, paper, metal and other materials with its high precision, high flexibility and intelligent functions. The following are the application analysis and technical highlights for different materials:

1. Film material slitting: high-precision and non-damage processing

Typical Applications:

• Optical films (e.g. display polarizers, brightness enhancement films)

• Packaging film (food-grade PE film, aluminum-plastic composite film)

• New energy films (lithium battery separators, photovoltaic backsheets)

Technical Requirements & Solutions:

| challenge | Intelligent slitting scheme |

| Extremely thin and easily deformable (thickness ≤ 5 μm) | Air flotation tension control + static elimination device to avoid film stretching or wrinkling |

| Dust-free and pollution-free | Closed clean cavity + ionized air knife cleaning, meeting semiconductor/medical grade requirements |

| No burrs on the edges | Nanoscale diamond tools or laser cutting (cold working) to avoid heat-affected zones (e.g. PI films) |

Case:

The slitting of lithium battery separator needs to ensure an accuracy of ±1μm, and ultrasonic online detection + AI real-time deviation correction is used to prevent the battery from short circuit caused by microporous tearing of the separator.

2. Paper slitting: high efficiency and adaptability upgrade

Typical Applications:

• Specialty paper (label paper, thermal paper)

• Packaging cardboard (corrugated, cardboard)

• Cultural paper (book printing, art paper)

Technical Requirements & Solutions:

| challenge | Intelligent slitting scheme |

| Multi-layer composite slitting | Pressure-adjustable round knife system that automatically matches different lamination strengths (e.g. Tetra Pak foil) |

| Prevents dust build-up | Integrated vacuum adsorption device + automatic dust removal tool holder to ensure the cleanliness of cutting |

| The need for rapid changeovers | The modular turret design, combined with the HMI preset parameters, shortens the changeover time to less than 5 minutes |

Case:

The visual positioning system is used to accurately align the metallic gloss texture and improve the consistency of the appearance of luxury packaging.

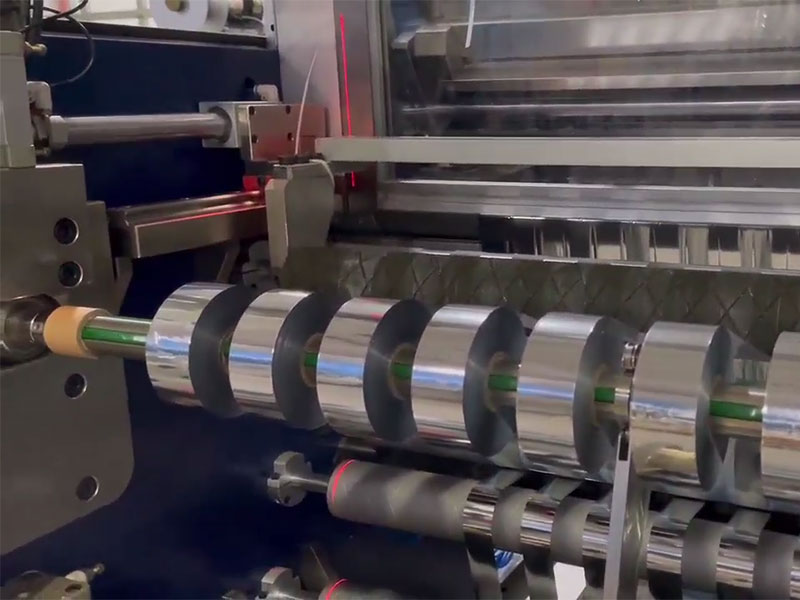

3. Slitting of metal materials: high strength and precision machining

Typical Applications:

• Metal foils (copper foils, aluminum foils, for PCB or battery current collectors)

• Sheet strip (stainless steel strip, silicon steel sheet)

• Composites (metal-plastic laminates)

Technical Requirements & Solutions:

| challenge | Intelligent slitting scheme |

| Hard material tool wear | Tungsten carbide coated tool + automatic wear compensation system, 300% longer life |

| Cutting heat distortion control | Liquid nitrogen-cooled cutting technology or pulsed laser cutting to avoid metal oxidation (e.g. ultra-thin copper foil ≤8μm) |

| Coil stress relief | Multi-stage tension partition control, with elastic pressure rollers to prevent metal coil warping |

Case:

The copper foil slitting of new energy batteries adopts flying shear technology, with a speed of 120m/min and a burr height of ≤3μm, which meets the requirements of high energy density battery pole pieces.

Fourth, cross-material general intelligent technology

1. Hybrid slitting mode:

◦ The same device is compatible with the cutting needs of film, paper, and metal through quick-change modules (e.g., knife shafts → laser heads).

2. Intelligent Detection Closed Loop:

◦ Multispectral sensors (such as near-infrared + X-ray) can simultaneously detect material defects, thickness, and humidity, and adjust process parameters in real time.

3. Digital Twin Optimization:

◦ Virtually simulate the cutting process to predict the stress distribution of the material after slitting (e.g., edge residual stress after slitting of metal coils).

Fifth, the cutting-edge trend of the industry

• Ultra-narrow slitting: the minimum slitting width is up to 0.1mm (e.g. copper foil for RFID antennas).

• Green cutting: Dry slitting technology replaces traditional lubricants and reduces chemical contamination (for food packaging films).

• AI whole-process control: from raw material warehousing to slitting finished products, fully automatic matching of process parameters (such as direct instructions issued by the MES system).

Summary: The core value of the versatility of the slitter

• Quality dimensions: edge quality, dimensional accuracy, material utilization.

• Efficiency dimension: changeover speed, cutting speed, degree of automation.

• Economic dimension: tool life, energy optimization, labor cost reduction.

Through modular design and intelligent upgrading, modern slitting machines have evolved from a single-function equipment to an all-round processing platform covering flexible materials→ hard materials → composite materials, and have become an indispensable part of high-end manufacturing.

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026

This is not only an iteration of equipment, but also a comprehensive redefinition of production efficiency, material utilization and intelligent management standards.

27. February, 2026

It is in this context that the new generation of ribbon slitting machines is redefining the production standards of the industry with "precision manufacturing" as the core.

27. February, 2026

this once management pain point is now transforming into a powerful tool for printing enterprises to reduce costs and increase efficiency.

26. February, 2026

This article will delve into how to make the hot foil slitting machine the engine of your production process optimization through scientific equipment selection and management.

26. February, 2026