Overview of modular design

The modular design of the capacitor film slitting machine is to decompose the whole machine into multiple module units with independent functions and standardized interfaces, and realize the flexible configuration of equipment functions through the combination of different modules. This design concept significantly improves the adaptability and maintainability of the equipment.

Main module division

1. Unwinding module

◦ Equipped with automatic web guiding system

◦ The tension control unit is packaged separately

◦ Core-based adapters can be quickly replaced

2. Slitting module

◦ Standardized design of tool holder

◦ Configurable with different cutting methods (pneumatic/mechanical/laser)

◦ Modular tooling system for quick changeovers

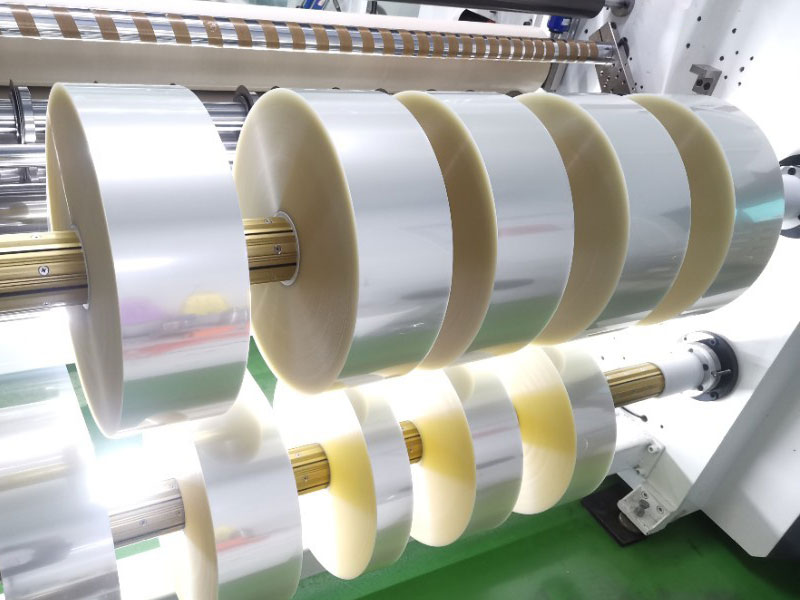

3. Winding module

◦ Independent drive system

◦ Expandable multi-station winding

◦ Modular tension control system

4. Control system

◦ Distributed I/O modules are used

◦ Each functional module controls the unit independently

◦ Standard communication interfaces

Flexible configuration advantages

1. Product adaptability

◦ Films of different widths (5-1000 mm) and thicknesses (2-100 μm) can be processed by changing the module

◦ Quickly switch between production configurations for different materials (PP/PE/PET, etc.).

2. Capacity expansion

◦ Slitting knife set modules can be stacked and increased

◦ The winding station can be expanded as needed

◦ Control system capacity reservation expansion interface

3. Functional customization

◦ On-line detection module is optional

◦ A surface treatment module can be added

◦ Flexible integration of dust and static removal unit

Designed for ease of maintenance

1. Quick system change

◦ Standardized mechanical interfaces between modules

◦ Push-in fittings are used for electrical connections

◦ Drawer design for key components

2. Diagnostic and maintenance support

◦ Independent fault indicator for each module

◦ Modular PLC program structure

◦ Module-level fault diagnosis is supported

3. Simplified spare parts management

◦ Standardized modules reduce the variety of spare parts

◦ Module serial number tracking management

◦ Predictive maintenance interface

Implementation benefits

1. The time to change equipment configuration is reduced by more than 60%.

2. 40-50% reduction in mean time to repair (MTTR)

3. 15-20% increase in equipment utilization

4. The efficiency of product switching has been significantly improved

The modular design enables the capacitor film slitter to quickly respond to market changes and customer customization needs, while significantly reducing the operating costs throughout the life cycle.

The tool holder driven by servo motor can achieve a positioning accuracy of ±0.01mm, reducing the burr on the edge of the film.

21. June, 2025

It has evolved from a single processing equipment to an intelligent production unit integrating perception, decision-making and execution.

20. June, 2025

The following is a professional analysis from three aspects: technical characteristics, application scenarios and industry trends:

19. June, 2025

high-precision slitting (accuracy ± 1μm) and tension control (±0.5N) ensure that the film is not damaged.

18. June, 2025

The key to improving the productivity of capacitor film slitting machines is to optimize the tool change process and realize automatic adjustments

17. June, 2025