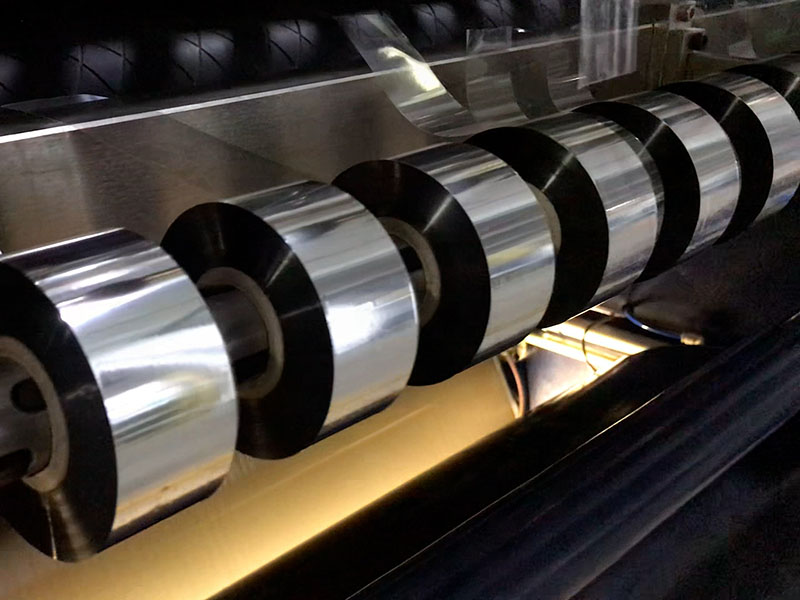

We know that the use of slitting machine is useful for many products in processing, but in the selection we also have to master some selection skills for high-quality equipment.

1. Understand and recognize the advantages and disadvantages of each manufacturer

Different manufacturers, the specific technical capabilities will be different, we should actively pay attention to understand and know the technical capabilities of manufacturers (scientific research strength, production strength, team service, etc.), in order to make the best choice. When purchasing slitting machines, a simple way is not only to look at the reputation of the manufacturer in the industry, but also to compare according to product parameters and pictures. If you have a correct understanding and understanding of the products of different manufacturers, you will be able to choose manufacturers more accurately.

2. Compare the products of different manufacturers

For the same product, the quality of the products produced by different manufacturers is not the same, so if you want to know which one has better product quality and higher cost performance, you need some patience, and do a comprehensive understanding and comparison of product parameters and physical performance, so that the choice will become more accurate and simple.

3. Don't be greedy for cheap and lose big because of small things

According to the needs of the enterprise, we should do a good job in understanding and understanding all aspects of the slitting machine, pay attention to our actual situation, and avoid entering various misunderstandings when buying the slitting machine. Sometimes we don't know enough about the product, and sometimes we will be greedy for cheap and lose big because of small things, these misunderstandings will have a negative impact on us. Don't think about buying cheap products when purchasing, after all, you get what you pay for, and moderate prices will be more applicable. As a professional purchaser, you should pay extra attention to the natural purchase of better quality products.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026