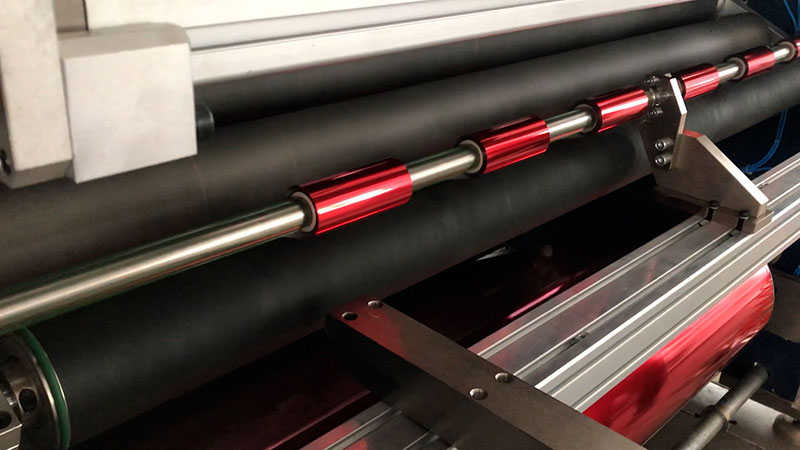

Slitting machine is a kind of mechanical equipment that slits wide paper, mica tape or film into multiple narrow strips, and is commonly used in papermaking machinery, wire and cable mica tape and printing and packaging machinery.

Slitting machine standard operation manual:

1. The slitting machine sets the shutdown and deceleration parameters and starts the equipment. Use the P1 function of the color counter to set the distance from the label, and the actual distance value should be × 2 when setting. After the machine is stopped, use a ruler to measure the error distance of the upper and lower color scales.

2. Press the benchmarking button again, the slitting machine will automatically return the label according to the memory data, after the end of the label withdrawal action, move the lower photoelectric switch to the middle position of the color mark, and adjust the sensitivity of the photoelectric switch to complete.

3. Build according to the settings, and the color code will be automatically aligned according to the set value. Move the slitting machine to the right end of the benchmarking switch, start the equipment to complete a roll, if there is an error, just move the photoelectric switch accordingly. For example, if the color scale of the next layer exceeds the color scale of the upper layer by 5 mm, you only need to move it down by 5 mm.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026